Different types of biological fertilizers have different uses. The amount of pure biological fertilizer is less, generally 0.5-2 kg per mu, used for seed dressing, root or leaf spraying. For example, Soybean Rhizobium fertilizer can be inoculated by slurry method. Generally speaking, 30-75 kg / mu is used as seed fertilizer for mechanical sowing. Generally speaking, the amount of bio organic fertilizer is large, 50-80 kg / mu is used as basic fertilizer. When bio organic fertilizer was used as basic fertilizer in dry land, it was applied in autumn and spring in combination with the whole field. Paddy field is used as basic fertilizer and biological fertilizer is applied once before water.

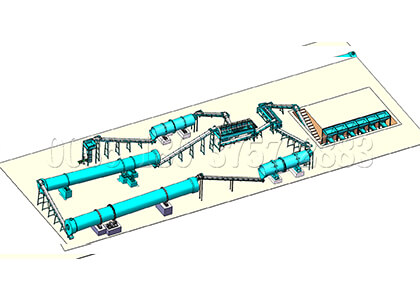

Biological fertilizer production line can adopt different raw materials and processes to make special fertilizer suitable for different crops. In the batch processing stage of biological fertilizer production, NPK inorganic fertilizer and other nutrients needed by crops are added and granulated by chemical fertilizer granulator, which can be processed into bio organic inorganic compound fertilizer. Bio organic inorganic compound fertilizer combines the dual advantages of organic fertilizer and inorganic fertilizer, which ensures that crops can obtain nutrition in short term and fertilizer effect in long-term supply. The fertilizer granulator of the biological fertilizer production process makes the raw materials into granules, which is convenient for the storage and use of the products.

Application of biological fertilizer

1. The manufacturer of chemical fertilizer machine reminds you that the effect of applying bio organic fertilizer on the basis of conventional fertilization is the best, and biological fertilizer should be applied continuously. If the fruit trees need phosphorus and potassium, not only can not reduce phosphorus and potassium fertilizer, but also increase phosphorus and potassium fertilizer appropriately. In the application of P and K, some soil lacking P and K should be increased. The combination of biological fertilizer, organic fertilizer and inorganic fertilizer has the best promoting effect on crops.

2. It should be noted that due to the nature of biological fertilizer, it should not be mixed with ammonium bicarbonate, plant ash, potassium sulfate, ammonium sulfate, etc., otherwise, the fertilizer efficiency of bacterial fertilizer will be affected.

3. When biological fertilizer is used as basic fertilizer or top sheet, it should be covered with soil in time to avoid affecting fertilizer efficiency. Want to get to know bio-fertilizer production process, welcome to https://organicfertilizerplants.com/bio-organic-fertilizer-production/