Disc granulator is one of the important equipment for organic fertilizer production. Its main working part is a rotating swashplate. According to the principle of agglomeration granulation of powdery materials, the powdery materials with wet surface are continuously rolled or overturned in the disc granulator equipment, and mechanical extrusion is added to promote these powdery materials to gradually form particles.

This machine is one of the important fertilizer making equipment in compound fertilizer production. The disc granulator can be reasonably selected through the parameters of the granulating disc, so as to improve the product output and greatly reduce the product cost.

1、 Principle of disc granulator

The disc is installed at a certain angle of inclination. The material in the disc rolls rapidly with the rotation of the disc body. When it rises to the highest point, it falls vertically under the stop of the scraper. During the rotation of the disc, the particles press and roll with the disc wall under the action of centrifugal force. Due to these comprehensive mechanical extrusion, rolling and collision, powdery materials are gathered together to form a "mother ball" through the surface tension of the liquid phase.

With the increase of "mother ball", it gradually turns into complete particles, from small to small. The granulation process is completed until the particle size of the finished product overflows from the edge of the disc. Disc granulator has good classification function. It continuously makes powdery materials grow from the bottom of the pot to form particles and overflow into the outer pot. As the diameter of the outer disk increases, the linear velocity of the particles increases suddenly. The particles roll while rounding to form spherical particles. Larger particles are blocked by the discharge plate, will not overflow into the hopper, and will be sent to the next process by the belt conveyor.

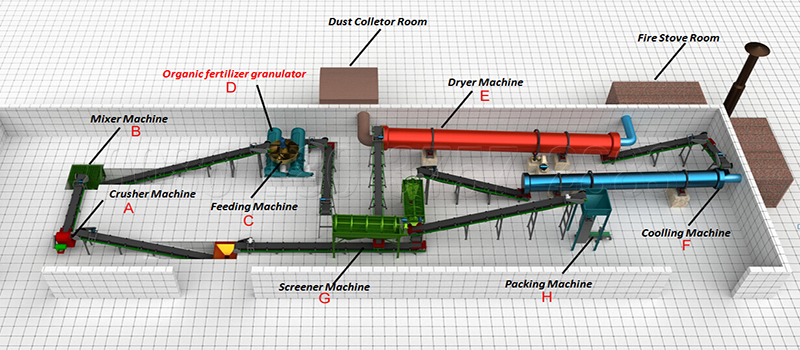

Many disc granulators are used in NPK fertilizer manufacturing process, but they can also be used in organic fertilizer manufacturing process.

2、 Technical parameters of disc granulator

In the production process, several parameters that will affect the granulation effect of the disc granulator are: disc diameter, disc height, inclination angle and disc speed.

Generally speaking, the diameter of the disc is mainly determined by the output. Each manufacturer shall select the combination matching with other organic fertilizer equipment such as mixer or screw conveyor according to its own situation, such as annual production capacity.

The annual production capacity of the disc granulator with a diameter of 2m can reach more than 10000 tons, and the annual production capacity of the disc granulator with a diameter of 2.2m can reach more than 15000 tons.

Therefore, the selection of disc diameter should be based on the design annual production capacity. Come and think about it. If the fertilizer granulator in the disc granulation production line is replaced by the strand granulator, this fertilizer production line is called drum granulation.

More detailed info, welcome go to https://www.fertilizer-plants.com/