The new fertilizer production line project should comprehensively consider local resources, market capacity and market coverage radius. In general, the annual output of small new plants is 10000 tons (1.5 tons / hour), 20000 tons (3 tons / hour) and 30000 tons (4.5 tons / hour). The annual output of medium-sized factories is 50000-100000 tons, and that of large-scale factories is 100000-300000 tons.

The investment scale and scheme design should be made according to the following conditions: raw material resource characteristics, local soil conditions, local planting structure and main crop varieties, plant site selection, NPK fertilizer granulator selection, production automation degree, etc.

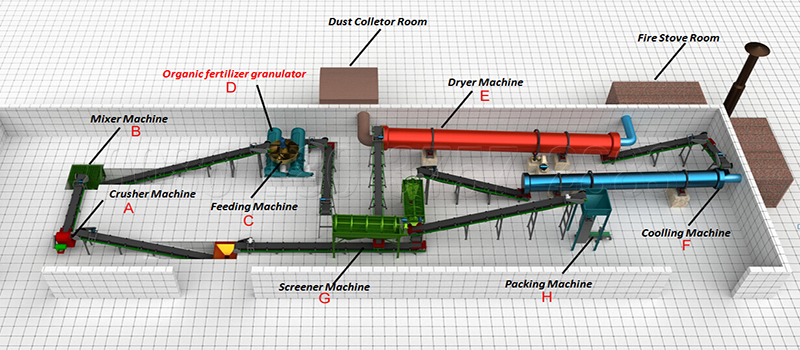

Fertilizer production line

Several equipments of chemical fertilizer production line

1. Mixer. In addition to chemical fertilizer raw materials, some cohesive materials, such as clay, can be properly added in the mixing process. During operation, the material is evenly mixed by stirring back and forth with multi-channel rotating blades.

2. Fertilizer granulator. Organic fertilizer granulator is generally used in small-scale production to meet the requirements.

3. The rotary dryer is mainly composed of drying cylinder, transmission device, support device and cylinder tail sealing parts. The diameter ranges from 80 cm to 3 m and the length depends on the drying requirements. The dryer is a cylinder inclined to a certain angle in the horizontal direction. The material is added from the high end, and the high temperature flue gas and the material enter the cylinder in parallel. As the cylinder rotates, the material moves to the lower end due to gravity. The lifting plate is welded on the inner wall of the cylinder to absorb and drop materials, and fully contact with hot air in the falling process to achieve the purpose of drying.

4. The rotary cooler can reduce the moisture content when cooling a certain temperature. It is the same as the dryer equipment, but uses space-time gas to pump from the head to the outside, so there is no need to seal the tail.

5. Combined screen is adopted for drum screen, which is convenient for maintenance and replacement. This machine has the advantages of simple structure, convenient operation and stable operation.