Composting Cow Manure Turns It In To A Good Organic Fertilizer That Benefits Plants

Cow dung or cattle manure is commonly used in numerous rural areas as fertilizer for agricultural produce. It really is a fertilizer that is certainly not very abundant in nitrogen, along with the high ammonia levels inside it can burn plants when the manure is fresh when it is applied. When the same manure is composted, it might be the sort of fertilizer that is certainly helpful to plants.

Most cattle manure is comprised of grain and digested grass. It is actually abundant in nutrients and possesses a very high content of organic materials. Considering its percentage of vital elements, it provides 3 percent of nitrogen, 2 percent of phosphorus, and simply a percent of potassium. Besides this, its content has several potentially dangerous pathogens along with high levels of ammonia. This is the main reason why the manure should be aged prior to it being used as fertilizer.

When you compost cow manure you can get rid of the ammonia from it plus assistance to remove ammonia gas which can be harmful and weeds and seeds that are thing about this manure, and also any dangerous pathogens like E.coli. The high content of organic matter that cow manure has, is included with the soil and may assistance in greatly improving its capacity to hold and retain moisture. This, consequently, minimizes the quantity of water that plants fertilized using this type of composted cow manure will need. It also helps in improving the aeration within the soil, and split up soil which has been compacted. Composted cow manure could have beneficial bacteria, that convert easily into nutrients which are easily accessed and release gradually, in order that plant roots which are tender will not get burnt.

To compost cow dung a spot where one can build a pile that is a minimum of 3 to 4 feet high, must be chosen. A 3-inch layer of dry organic material must first be spread from the chosen area. This has to be engrossed in a 2-inch layer of cow manure. This layering has to be continued before the pile is about four feet in height. The pile has to be watered and kept damp as you may construct it up and whenever the preferred height is reached it needs to be covered with a layer of soil.

The pile created should be turned over once every three days as well as its moistness maintained, without making the mass soggy. When you are turning on the pile, check its temperature at its center. It will be between 120 to 160 degrees Fahrenheit. The compost heap will gradually turn brown and may provide an earthy smell. At this time, you will find no heat produced at its center, and that means the compost is ready to be used.

When the compost pile is not going to warm, it means it has a smaller amount of manure and this has to be added. Excessive manure will make your pile stop trying an unpleasant and powerful odor. Increase the amount of of organic material.

It may always assist to create compost in the bin as it helps to contain the compost. Ensure that your compost pile is not any more heating up prior to using it on your plants.

Compost Making Tech, introduces you all the leading compost production technologies, facilities, formulars you want to know

Friday, 28 February 2020

Thursday, 27 February 2020

Animal Manure Quick Compost Methods

Steps To Make Animal Manure Compost

Among the best ways to manage animal manure is always to turn it into compost. This compost can be used in a variety of ways and you can easily enhance the soil quality when you use it. The compost is cheap to create plus it removes manure from your environment. Read on to learn the advantages of the manure compost machine.

In case you have plenty of animal manure to cope with it will be important to get it out of the environment straight away. The easiest method to do this is to try using an excellent composting plant.

The composting plant takes the manure and turns it into compost. The compost is the best thing you will need when you wish to help make extra income and do something useful. The most effective compost will likely be affordable and it also is going to be user friendly.

You have to make certain you buy a machine that lets you produce the compost. The composting plant comes in a variety of sizes and it creates compost that is great for a variety of needs.

Producing compost is not difficult when you have the correct composting plant. The plant makes the entire process automatic therefore you don't must do anything. When you find yourself choosing a composting plant you have to decide how much composting you might be doing. The plant comes in a number of sizes.

The main benefit of deciding on the composting machine is it shortens the amount of time it requires to produce the compost. You find yourself with higher-quality compost by using this machine. There are a number of machines you can use from so you will need to determine which machine will almost certainly work best for your requirements.

There are a variety of sizes from which to choose. When you have to make plenty of compost opt for the larger size. When you don't have a great deal of compost to help make you should select the machine that may be smaller. The price tag on the equipment will almost certainly rely on how big it can be and just how much compost it may produce.

Each machine has a self-propelled turner. This makes sure that you make the compost faster. The turner stirs the compost evenly so that it is released perfect every time. The machines let you adjust the temperature and you will also adjust the water and oxygen content.

The fermentation process will happen faster and you receive a simple four-wheel design making it an easy task to operate. The machine is going to enable you to create all of the compost you will need as well as the cost is affordable at the same time.

When you really need to make animal manure compost the most efficient technique of doing this can be employing a composting machine. You receive better produces a shorter time frame. This machine is a superb investment and really helps to earn more money. Finding the best composting machine will save you money.

Among the best ways to manage animal manure is always to turn it into compost. This compost can be used in a variety of ways and you can easily enhance the soil quality when you use it. The compost is cheap to create plus it removes manure from your environment. Read on to learn the advantages of the manure compost machine.

In case you have plenty of animal manure to cope with it will be important to get it out of the environment straight away. The easiest method to do this is to try using an excellent composting plant.

The composting plant takes the manure and turns it into compost. The compost is the best thing you will need when you wish to help make extra income and do something useful. The most effective compost will likely be affordable and it also is going to be user friendly.

You have to make certain you buy a machine that lets you produce the compost. The composting plant comes in a variety of sizes and it creates compost that is great for a variety of needs.

Producing compost is not difficult when you have the correct composting plant. The plant makes the entire process automatic therefore you don't must do anything. When you find yourself choosing a composting plant you have to decide how much composting you might be doing. The plant comes in a number of sizes.

The main benefit of deciding on the composting machine is it shortens the amount of time it requires to produce the compost. You find yourself with higher-quality compost by using this machine. There are a number of machines you can use from so you will need to determine which machine will almost certainly work best for your requirements.

There are a variety of sizes from which to choose. When you have to make plenty of compost opt for the larger size. When you don't have a great deal of compost to help make you should select the machine that may be smaller. The price tag on the equipment will almost certainly rely on how big it can be and just how much compost it may produce.

Each machine has a self-propelled turner. This makes sure that you make the compost faster. The turner stirs the compost evenly so that it is released perfect every time. The machines let you adjust the temperature and you will also adjust the water and oxygen content.

The fermentation process will happen faster and you receive a simple four-wheel design making it an easy task to operate. The machine is going to enable you to create all of the compost you will need as well as the cost is affordable at the same time.

When you really need to make animal manure compost the most efficient technique of doing this can be employing a composting machine. You receive better produces a shorter time frame. This machine is a superb investment and really helps to earn more money. Finding the best composting machine will save you money.

Wednesday, 26 February 2020

How to make pellet manure fertilizer?

Manure Granulators Are An Essential Part Of Manure Fertilizer Plants

If you're buying equipment to get a manure fertilizer plant, there's a certain piece of equipment that you'll want to prioritize: the manure granulator. This machine is definitely the backbone of the plant. Should you haven't purchased this equipment yet, it's important to choose it carefully.

Learn About Granulator Manufacturers

In order to get a granulator, you'll want for more information on the firms that can make these kinds of products. Investigating manufacturers and researching their history will help you get the brands that happen to be worth buying from.

One can learn a whole lot about various manufacturers by simply taking a closer inspection at their site. Look for a manufacturer which has successfully been producing most of these products for many years.

Locate A Machine That Meets Your Requirements

You should take your very own needs into consideration when you're buying a granulator. For example, you'll have to determine how much manure you'd love to produce everyday. The greater you understand about what you need, the better it will likely be so that you can get a machine you might be content with.

Don't be happy with a granulator that isn't good for you. If you need your plant to run smoothly, you're gonna desire to think carefully about what kind of machinery you want. Make time to find a granulator that may do exactly what you require it to do.

Consider The Measurements Of The Equipment

Space is usually going to be a consideration when you're purchasing machinery for the plant. You have to be sure you may have ample room for all the machinery that you're going to be using, particularly the granulator. You should look closely at the proportions of any granulators you're thinking about buying. You need to determine the dimensions of the room your plant will likely be based in.

Picking a granulator that's the wrong size will cause a myriad of trouble for you. Make sure you side-step most of these problems and find a granulator that's the perfect size for yourself.

Find The Best Options Which Can Be Affordable

What exactly are you comfortable spending on a granulator? Should you haven't set a spending budget, you'll wish to accomplish that sooner as an alternative to later. When you know what your range of prices is, you'll be capable of consider a few of the different choices that fall within that budget.

You will discover granulators at plenty of different price points, this is why you'll desire to aim to get what you need for the reasonable price. Make a reasonable budget and do your very best to stay within it. Focus your attention on machinery that you could actually afford to buy.

Ensure that you find the appropriate manure granulator to your poultry manure fertilizer plant. It is an essential piece of machinery, and you'll want to make certain that you can trust the machinery that you simply choose. Keep these suggestions at heart so that you'll be capable of choose the proper equipment.

If you're buying equipment to get a manure fertilizer plant, there's a certain piece of equipment that you'll want to prioritize: the manure granulator. This machine is definitely the backbone of the plant. Should you haven't purchased this equipment yet, it's important to choose it carefully.

Learn About Granulator Manufacturers

In order to get a granulator, you'll want for more information on the firms that can make these kinds of products. Investigating manufacturers and researching their history will help you get the brands that happen to be worth buying from.

One can learn a whole lot about various manufacturers by simply taking a closer inspection at their site. Look for a manufacturer which has successfully been producing most of these products for many years.

Locate A Machine That Meets Your Requirements

You should take your very own needs into consideration when you're buying a granulator. For example, you'll have to determine how much manure you'd love to produce everyday. The greater you understand about what you need, the better it will likely be so that you can get a machine you might be content with.

Don't be happy with a granulator that isn't good for you. If you need your plant to run smoothly, you're gonna desire to think carefully about what kind of machinery you want. Make time to find a granulator that may do exactly what you require it to do.

Consider The Measurements Of The Equipment

Space is usually going to be a consideration when you're purchasing machinery for the plant. You have to be sure you may have ample room for all the machinery that you're going to be using, particularly the granulator. You should look closely at the proportions of any granulators you're thinking about buying. You need to determine the dimensions of the room your plant will likely be based in.

Picking a granulator that's the wrong size will cause a myriad of trouble for you. Make sure you side-step most of these problems and find a granulator that's the perfect size for yourself.

Find The Best Options Which Can Be Affordable

What exactly are you comfortable spending on a granulator? Should you haven't set a spending budget, you'll wish to accomplish that sooner as an alternative to later. When you know what your range of prices is, you'll be capable of consider a few of the different choices that fall within that budget.

You will discover granulators at plenty of different price points, this is why you'll desire to aim to get what you need for the reasonable price. Make a reasonable budget and do your very best to stay within it. Focus your attention on machinery that you could actually afford to buy.

Ensure that you find the appropriate manure granulator to your poultry manure fertilizer plant. It is an essential piece of machinery, and you'll want to make certain that you can trust the machinery that you simply choose. Keep these suggestions at heart so that you'll be capable of choose the proper equipment.

Wednesday, 19 February 2020

How to make granular fertilizer?

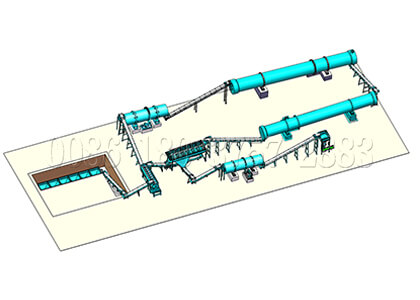

What Must You Plan For Establishing A Fertilizer Pellet Production Line

A fertilizer production lines are an activity of turning organic waste including cattle or poultry manure into fertilizer. On the whole, the whole fertilizer making process contains a compost turner, a crusher, mixer, granulator, screening machine, a drying-and-cooling machine, and bagging equipment. To generate superior fertilizer pellets, it is additionally easy to implement a fertilizer coating-machine.

The fertilizer production line is the perfect choice to process vermicompost, cow dung, and chicken manure into fertilizer. This procedure not simply gives a solution to eradicate excess waste but in addition offers a way to generate income from the end product.

The Manufacturing Process For Granular Fertilizer

The production line for granular fertilizers is a lot more complex when compared with manufacturing powder fertilizers. The entire manufacturing process for producing granular fertilizers involves three phases.

The first step involves the pre-treating process, which needs a turning machine, plus a crusher and mixer. The second phase of your process includes the granulator as well as the drying-and-cooling machine. The very last stage contains a screening machine and bagging equipment.

How You Can Make Fertilizer Pellets Having A Fertilizer Production Line

1.Fermentation Process

Fermentation is the initial process found in the development line. Fermentation is necessary for organic waste to eliminate diseases and pests. Additionally, fully fermented organic matter makes it easier for crops and plants to absorb the nutrients within the organic manure. This area of the process requires the compost turner that can take around 2 weeks to complete.

2.Crushing Process

The crushing equipment used for fertilizer plays an important role in terms of the entire production process. This machine can crush manure just before the fermentation process. The crushing machine is also accustomed to break-up the materials that are already fermented preparing the raw materials to the granulator.

3.Mixing Process

The function of this area of the production lines are to combine the raw materials when preparing for that pelletizing process. The mixers can be purchased in either a horizontal mixer or even a disc mixer.

4.Granulating Process

This is actually the second primary process from the fertilizer production line. Throughout these procedures, a conveyor is utilized to move the raw materials that are now in the powdered form in a pelletizing machine for granulating.

5.Pellet Screening Process

To ensure your customers only get the highest-quality fertilizer, it is actually a wise choice to purchase a fertilizer-screener for the production plant. This machinery will help with screening out unqualified products.

6.Pellet Packing Process

The last stage within the production line to make fertilizer pellets includes packing the pellets into bags. The bagging equipment currently available through several manufacturers allows you to bag your fertilizer into different sized bags. These include 5kg, 15kg, 25kg plus more.

Organic fertilizers are rich in peptides, organic acid, potassium, phosphorus, and nitrogen. That is why, organic animal waste such as manure is probably the ideal way to provide nutrition to plants and crops. Also, it is the solution to eradicate animal waste that is acknowledged for attracting diseases and pests.

A fertilizer production lines are an activity of turning organic waste including cattle or poultry manure into fertilizer. On the whole, the whole fertilizer making process contains a compost turner, a crusher, mixer, granulator, screening machine, a drying-and-cooling machine, and bagging equipment. To generate superior fertilizer pellets, it is additionally easy to implement a fertilizer coating-machine.

The fertilizer production line is the perfect choice to process vermicompost, cow dung, and chicken manure into fertilizer. This procedure not simply gives a solution to eradicate excess waste but in addition offers a way to generate income from the end product.

The Manufacturing Process For Granular Fertilizer

The production line for granular fertilizers is a lot more complex when compared with manufacturing powder fertilizers. The entire manufacturing process for producing granular fertilizers involves three phases.

The first step involves the pre-treating process, which needs a turning machine, plus a crusher and mixer. The second phase of your process includes the granulator as well as the drying-and-cooling machine. The very last stage contains a screening machine and bagging equipment.

How You Can Make Fertilizer Pellets Having A Fertilizer Production Line

1.Fermentation Process

Fermentation is the initial process found in the development line. Fermentation is necessary for organic waste to eliminate diseases and pests. Additionally, fully fermented organic matter makes it easier for crops and plants to absorb the nutrients within the organic manure. This area of the process requires the compost turner that can take around 2 weeks to complete.

2.Crushing Process

The crushing equipment used for fertilizer plays an important role in terms of the entire production process. This machine can crush manure just before the fermentation process. The crushing machine is also accustomed to break-up the materials that are already fermented preparing the raw materials to the granulator.

3.Mixing Process

The function of this area of the production lines are to combine the raw materials when preparing for that pelletizing process. The mixers can be purchased in either a horizontal mixer or even a disc mixer.

4.Granulating Process

This is actually the second primary process from the fertilizer production line. Throughout these procedures, a conveyor is utilized to move the raw materials that are now in the powdered form in a pelletizing machine for granulating.

5.Pellet Screening Process

To ensure your customers only get the highest-quality fertilizer, it is actually a wise choice to purchase a fertilizer-screener for the production plant. This machinery will help with screening out unqualified products.

6.Pellet Packing Process

The last stage within the production line to make fertilizer pellets includes packing the pellets into bags. The bagging equipment currently available through several manufacturers allows you to bag your fertilizer into different sized bags. These include 5kg, 15kg, 25kg plus more.

Organic fertilizers are rich in peptides, organic acid, potassium, phosphorus, and nitrogen. That is why, organic animal waste such as manure is probably the ideal way to provide nutrition to plants and crops. Also, it is the solution to eradicate animal waste that is acknowledged for attracting diseases and pests.

Tuesday, 18 February 2020

How to make bulk blending fertilizer?

The Importance Of Deciding On The Best Bulk Blending Fertilizer Production Line Supplier To Make Premium Quality Mixed Fertilizers

Bulk blending involves mixing together several granulated fertilizers mechanically to generate a better quality mixed fertilizer. The conclusion product will contain a mixture of essential plant nutrients, including nitrogen, phosphorous and potassium. This process allows for small batches of crop-specific fertilizers and analysis soil samples to become mixed, stored and transported in an efficient manner. Farmers can easily maximize profits by utilizing good quality mixed fertilizer. What's more, organic mixed fertilizers will help you to protect the surroundings, while they contain more balanced nutrient profiles than single blend non-organic fertilizers.

For effective bulk blending, the raw materials must be well granulated, have roughly a similar sized particles and be dry in order to avoid caking, segregation and deterioration. High-grade bulk blended fertilizers are non-hygroscopic and never emit dust. They contain a nutrient profile that reflects the stated breakdown percentages around the label and so they tend not to segregate during handling. Furthermore, the nutrients are homogeneously mixed, so each granule has got the same nutrient profile.

The most important problems that arise during bulk blending processes are segregation and uneven distribution of secondary micronutrients. Segregation can happen in storage silos from vibrations or on account of coning action. All of the micronutrient additives should be sprayed onto blended fertilizers employing a tacky substance. The harmful chemicals from the raw ingredients for bulk blends have to be chemically compatible. Ammonium nitrate and urea, by way of example, ought not to be combined as a result of wetting.

Bulk blending is popular from the fertilizer industry because the process is simple and easy the original investment costs for equipment are relatively low. Because of the fact that the mixed fertilizers made by factories are nutrient-dense materials with few fillers, transportation and storage costs are reduced. Prescription blends are usually in high demand from farmers, as they possibly can increase crop yields significantly and so deliver farmers higher annual profits. The are lots of fertilizer manufacturing companies focusing on mixed prescription blend fertilizers.

In case you are already running an organic compound fertilizer production line, expanding in to the mixed fertilizer market could help you to improve your profits. However, in relation to manufacturing top quality mixed fertilizers, you need to choose the best bulk blending fertilizer production line supplier. You need to buy high-quality granulating equipment as well as machinery that will mix dry fertilizer materials together uniformly. To make your production line more effective, you may decide to select a bag filling machine. The equipment will weigh end products and seal filled bags for convenient distribution.

The best fertilizer production line equipment suppliers are based in China. You are able to get low price and-quality machinery from Chinese suppliers. Modern blending facilities routinely have 4 ton to 9-ton capacity mixers. With a 9 ton mixer, it can be easy to manufacture over 45 a lot of blended fertilizer each hour. Make sure to take a look at every one of the key parameters - including capacity, power, lift power, and applications - of bulk blending fertilizer mixing equipment on the market online become creating a purchase.

Bulk blending involves mixing together several granulated fertilizers mechanically to generate a better quality mixed fertilizer. The conclusion product will contain a mixture of essential plant nutrients, including nitrogen, phosphorous and potassium. This process allows for small batches of crop-specific fertilizers and analysis soil samples to become mixed, stored and transported in an efficient manner. Farmers can easily maximize profits by utilizing good quality mixed fertilizer. What's more, organic mixed fertilizers will help you to protect the surroundings, while they contain more balanced nutrient profiles than single blend non-organic fertilizers.

For effective bulk blending, the raw materials must be well granulated, have roughly a similar sized particles and be dry in order to avoid caking, segregation and deterioration. High-grade bulk blended fertilizers are non-hygroscopic and never emit dust. They contain a nutrient profile that reflects the stated breakdown percentages around the label and so they tend not to segregate during handling. Furthermore, the nutrients are homogeneously mixed, so each granule has got the same nutrient profile.

The most important problems that arise during bulk blending processes are segregation and uneven distribution of secondary micronutrients. Segregation can happen in storage silos from vibrations or on account of coning action. All of the micronutrient additives should be sprayed onto blended fertilizers employing a tacky substance. The harmful chemicals from the raw ingredients for bulk blends have to be chemically compatible. Ammonium nitrate and urea, by way of example, ought not to be combined as a result of wetting.

Bulk blending is popular from the fertilizer industry because the process is simple and easy the original investment costs for equipment are relatively low. Because of the fact that the mixed fertilizers made by factories are nutrient-dense materials with few fillers, transportation and storage costs are reduced. Prescription blends are usually in high demand from farmers, as they possibly can increase crop yields significantly and so deliver farmers higher annual profits. The are lots of fertilizer manufacturing companies focusing on mixed prescription blend fertilizers.

In case you are already running an organic compound fertilizer production line, expanding in to the mixed fertilizer market could help you to improve your profits. However, in relation to manufacturing top quality mixed fertilizers, you need to choose the best bulk blending fertilizer production line supplier. You need to buy high-quality granulating equipment as well as machinery that will mix dry fertilizer materials together uniformly. To make your production line more effective, you may decide to select a bag filling machine. The equipment will weigh end products and seal filled bags for convenient distribution.

The best fertilizer production line equipment suppliers are based in China. You are able to get low price and-quality machinery from Chinese suppliers. Modern blending facilities routinely have 4 ton to 9-ton capacity mixers. With a 9 ton mixer, it can be easy to manufacture over 45 a lot of blended fertilizer each hour. Make sure to take a look at every one of the key parameters - including capacity, power, lift power, and applications - of bulk blending fertilizer mixing equipment on the market online become creating a purchase.

Monday, 17 February 2020

Organic Waste Composting

How you can Manage Great deal of Organic Waste by Composting

Waste management is a significant issue that countless people can’t handle. Moreover, people don’t know how to use organic waste. Similarly, everyone is worried about recycling and reusing, however are not aware of how you can manage organic waste. Well, a good way to undertake it is composting. This procedure involves three R’s: reuse, reduce, and recycle.

Composting organic waste

Need to know how composting fits the 3 R’s? When you send massive quantities of garbage towards the landfill, it really is decreasing the total number of organic waste. The landfill operator reuses the organic matter instead of dumping it further. So, in addition, it ticks the “reuse” box too. Lastly, many manufacturers recycle the organic matter into a useful soil amendment. They are fertilizers that will help to make high-quality crop utilized by 1000s of farmers around the world.

Why composting is important?

Ecosystems usually breakdown organic materials and convert them into decomposers. These decomposers, obtainable in the food chain, breakdown the organic waste and turn them into humus, which is among the essential parts of crop soil.

Although this process seems simple enough, it will require environmental surroundings months to transform organic waste into humus. However, you should use your composting skills to have the same result quickly. This process boosts the speed of decomposition to ensure that organic waste decays easily.

How to compost organic waste?

Composting organic waste is a relatively easy process. Here’s what you must do:

• Spread the organic waste on bare earth. Naturally, don’t spread it over a cement or concrete floor. Ideally, you should keep organic waste on existing soil so that worms along with other microorganisms can decompose the waste.

• Dig the soil a couple of inches and lay a bed of twigs and straw. This can help in aerating the pile and also facilitates draining wastewater.

• Add compost materials on organic waste. Be sure to add both dry and moist materials inside the mix. A few of the common compost materials are seaweed, tea bags, food scraps, etc. But, don’t add plastic like chocolate wrappers, chips packets, and the like other things. You ought to include some dry compost materials like sawdust pellets, wood ashes, leaves, straw, etc. These assistance to breakdown the organic waste quickly.

• Add manure to the organic waste. Try purchasing green manure, including wheatgrass, buckwheat, grass clippings, or clover. These are generally excellent causes of nitrogen. You may also use cow dung powder. These assistance to activate the composting process.

•If it doesn’t rain, water the composts occasionally.

•Be sure you use a protective covering to help you retain heat and moisture. Exposing the compost to sunlight can reduce the process.

•Don’t forget to make the organic matter every week. Use a shovel or pitchfork to aerate the pile. This speeds the composting process.

A lot of people likewise use composters where they add each of the ingredients, as well as the machine does all of those other job. It requires less time as well as produces high-quality compost.

Waste management is a significant issue that countless people can’t handle. Moreover, people don’t know how to use organic waste. Similarly, everyone is worried about recycling and reusing, however are not aware of how you can manage organic waste. Well, a good way to undertake it is composting. This procedure involves three R’s: reuse, reduce, and recycle.

Composting organic waste

Need to know how composting fits the 3 R’s? When you send massive quantities of garbage towards the landfill, it really is decreasing the total number of organic waste. The landfill operator reuses the organic matter instead of dumping it further. So, in addition, it ticks the “reuse” box too. Lastly, many manufacturers recycle the organic matter into a useful soil amendment. They are fertilizers that will help to make high-quality crop utilized by 1000s of farmers around the world.

Why composting is important?

Ecosystems usually breakdown organic materials and convert them into decomposers. These decomposers, obtainable in the food chain, breakdown the organic waste and turn them into humus, which is among the essential parts of crop soil.

Although this process seems simple enough, it will require environmental surroundings months to transform organic waste into humus. However, you should use your composting skills to have the same result quickly. This process boosts the speed of decomposition to ensure that organic waste decays easily.

How to compost organic waste?

Composting organic waste is a relatively easy process. Here’s what you must do:

• Spread the organic waste on bare earth. Naturally, don’t spread it over a cement or concrete floor. Ideally, you should keep organic waste on existing soil so that worms along with other microorganisms can decompose the waste.

• Dig the soil a couple of inches and lay a bed of twigs and straw. This can help in aerating the pile and also facilitates draining wastewater.

• Add compost materials on organic waste. Be sure to add both dry and moist materials inside the mix. A few of the common compost materials are seaweed, tea bags, food scraps, etc. But, don’t add plastic like chocolate wrappers, chips packets, and the like other things. You ought to include some dry compost materials like sawdust pellets, wood ashes, leaves, straw, etc. These assistance to breakdown the organic waste quickly.

• Add manure to the organic waste. Try purchasing green manure, including wheatgrass, buckwheat, grass clippings, or clover. These are generally excellent causes of nitrogen. You may also use cow dung powder. These assistance to activate the composting process.

•If it doesn’t rain, water the composts occasionally.

•Be sure you use a protective covering to help you retain heat and moisture. Exposing the compost to sunlight can reduce the process.

•Don’t forget to make the organic matter every week. Use a shovel or pitchfork to aerate the pile. This speeds the composting process.

A lot of people likewise use composters where they add each of the ingredients, as well as the machine does all of those other job. It requires less time as well as produces high-quality compost.

Saturday, 15 February 2020

Complete Ways to Make Fertilizer Granule System

A fertilizer production line is a process of turning organic waste such as cattle or poultry manure into fertilizer. On the whole, the complete fertilizer making process contains a compost turner, a crusher, mixer, granulator, screening machine, a drying-and-cooling machine, and bagging equipment. To produce superior fertilizer pellets, it is additionally easy to implement a fertilizer coating-machine.

The fertilizer production line is the best choice to process vermicompost, cow dung, and chicken manure into fertilizer. This procedure not only provides a solution to eliminate excess waste and also offers a method to generate profits off of the end product.

The Manufacturing Process For Granular Fertilizer

The production line for granular fertilizers is far more complex in comparison to manufacturing powder fertilizers. The entire manufacturing process for producing granular fertilizers involves three phases.

The initial step necessitates the pre-treating process, which needs a turning machine, as well as a crusher and mixer. The next phase in the process includes the granulator and also the drying-and-cooling machine. The last stage features a screening machine and bagging equipment.

Steps To Make Fertilizer Pellets By Using A Fertilizer Production Line

1.Fermentation Process

Fermentation is definitely the initial process found in the development line. Fermentation is needed for organic waste to reduce diseases and pests. Additionally, fully fermented organic matter makes it easier for crops and plants to soak up the nutrients within the organic manure. This part of the process involves the compost turner which can take around 2 weeks to accomplish.

2.Crushing Process

The crushing equipment employed for fertilizer plays a crucial role in terms of the overall production process. This machine is able to crush manure before the fermentation process. The crushing machine can also be used to break-up materials that are already fermented preparing the raw materials for the granulator.

3.Mixing Process

The purpose of this area of the production lines are to mix the raw materials when preparing for that pelletizing process. The mixers can be found in either a horizontal mixer or possibly a disc mixer.

4.Granulating Process

This is the second primary process from the fertilizer production line. Through these procedures, a conveyor is used to move the raw materials that are now in a powdered form in to a pelletizing machine for granulating.

5.Pellet Screening Process

To make certain that your customers only get the highest-quality fertilizer, it is a wise choice to purchase a fertilizer-screener to your production plant. This machinery will help with screening out unqualified products.

6.Pellet Packing Process

The very last stage in the production line to generate fertilizer pellets includes packing the pellets into bags. The bagging equipment currently available through a variety of manufacturers allows you to bag your fertilizer into different sized bags. Such as 5kg, 15kg, 25kg and more.

Organic fertilizers are loaded with peptides, organic acid, potassium, phosphorus, and nitrogen. Because of this, organic animal waste for example manure is among the best ways to provide nutrition to plants and crops. Additionally it is the remedy to eliminate animal waste that is known for attracting diseases and pests.

The fertilizer production line is the best choice to process vermicompost, cow dung, and chicken manure into fertilizer. This procedure not only provides a solution to eliminate excess waste and also offers a method to generate profits off of the end product.

The Manufacturing Process For Granular Fertilizer

The production line for granular fertilizers is far more complex in comparison to manufacturing powder fertilizers. The entire manufacturing process for producing granular fertilizers involves three phases.

The initial step necessitates the pre-treating process, which needs a turning machine, as well as a crusher and mixer. The next phase in the process includes the granulator and also the drying-and-cooling machine. The last stage features a screening machine and bagging equipment.

Steps To Make Fertilizer Pellets By Using A Fertilizer Production Line

1.Fermentation Process

Fermentation is definitely the initial process found in the development line. Fermentation is needed for organic waste to reduce diseases and pests. Additionally, fully fermented organic matter makes it easier for crops and plants to soak up the nutrients within the organic manure. This part of the process involves the compost turner which can take around 2 weeks to accomplish.

2.Crushing Process

The crushing equipment employed for fertilizer plays a crucial role in terms of the overall production process. This machine is able to crush manure before the fermentation process. The crushing machine can also be used to break-up materials that are already fermented preparing the raw materials for the granulator.

3.Mixing Process

The purpose of this area of the production lines are to mix the raw materials when preparing for that pelletizing process. The mixers can be found in either a horizontal mixer or possibly a disc mixer.

4.Granulating Process

This is the second primary process from the fertilizer production line. Through these procedures, a conveyor is used to move the raw materials that are now in a powdered form in to a pelletizing machine for granulating.

5.Pellet Screening Process

To make certain that your customers only get the highest-quality fertilizer, it is a wise choice to purchase a fertilizer-screener to your production plant. This machinery will help with screening out unqualified products.

6.Pellet Packing Process

The very last stage in the production line to generate fertilizer pellets includes packing the pellets into bags. The bagging equipment currently available through a variety of manufacturers allows you to bag your fertilizer into different sized bags. Such as 5kg, 15kg, 25kg and more.

Organic fertilizers are loaded with peptides, organic acid, potassium, phosphorus, and nitrogen. Because of this, organic animal waste for example manure is among the best ways to provide nutrition to plants and crops. Additionally it is the remedy to eliminate animal waste that is known for attracting diseases and pests.

Friday, 14 February 2020

How to turn cow dung into fine powder?

The Best Way To Turn Cow Dung Into Powder Fertilizer?

Everywhere there are cows, you could always be sure of merely one thing, there may also always cow manure. As beef and dairy farming intensified, industrialized and specialized, the requirement to find urgent solutions for cow dung environmental pollution problems became real. Because of this, many machines were inverted to change cow dung into powder fertilizer.

Let's think about the fact than an average beef cattle unit produces around 10.5 a lot of manure annually, and an average dairy cow unit produces a lot more than 15.4 a great deal of manure annually. To place things into perspective, a major city with 410,000 residents produces less waste than the usual single dairy farm made up of 2,500 animals. Cow dung pollution is an important global problem. In some countries, pollution from cattle manure exceeds industrial pollution. A lot of people wrongly think that animal waste is "natural" so it's not dangerous, but that may be not the case.

Fortunately, cow dung can be transformed into a great organic fertilizer powder. It has each of the nutrients plants have to thrive and it's rich in organic matter. The NPK profile of cow dung is 1% potassium, 4% nitrogen, and 2% phosphorous. The other constitutes of cow dung besides micronutrients and organic matter are various enzymes and microorganisms. To be able to convert cow dung into fertilizer, specialized machines are often needed. The fertilizer produced can vastly improve soil structure and fertility. What's more, the fertilizer can promote healthy microbial growth and stop common root diseases and rot.

Cow manure is a great organic fertilizer, but if you set fresh cow dung on the soil, the huge amounts of ammonia produced could cause a horrible odor and burn crops. Additionally, unprocessed cow dung might be full of salt, dependant upon the diet the cattle were fed, which can be not ideal for crop growth. To generate a nutritious fertilizer, cow dung has to be composed. Natural fermentation of cow dung can take a long time, but fortunately, there is now a variety of modern composting machinery available on the market made to speed up the process.

Cow dung should be fully fermented before it is actually used on agricultural soil. Otherwise, it would cause soil temperatures to enhance, which could damage crop root systems. Furthermore, fresh cow dung is full of viruses and pathogens, which may be damaging to the surrounding environment and water supplies.

To turn cow manure right into a safe organic NPK powder fertilizer, it needs to be fully decomposed. The easiest way to compost cattle waste is to invest in the very best cow dung fertilizer machines, like self-propelled compost turners, hydraulic windrow turners, and dewatering machines.

High-grade NPK compound fertilizer is on the go which is relatively cheap to generate. By producing powder fertilizer from cow dung, you can help to handle the mounting global environmental pollution problems associated with mounting animal waste. What's more, together with the right equipment, powder fertilizer may be processed further into granules or pellets. Granules are easier to store and transport. Browse the latest granulation machines to finish your cow dung fertilizer production line.

Everywhere there are cows, you could always be sure of merely one thing, there may also always cow manure. As beef and dairy farming intensified, industrialized and specialized, the requirement to find urgent solutions for cow dung environmental pollution problems became real. Because of this, many machines were inverted to change cow dung into powder fertilizer.

Let's think about the fact than an average beef cattle unit produces around 10.5 a lot of manure annually, and an average dairy cow unit produces a lot more than 15.4 a great deal of manure annually. To place things into perspective, a major city with 410,000 residents produces less waste than the usual single dairy farm made up of 2,500 animals. Cow dung pollution is an important global problem. In some countries, pollution from cattle manure exceeds industrial pollution. A lot of people wrongly think that animal waste is "natural" so it's not dangerous, but that may be not the case.

Fortunately, cow dung can be transformed into a great organic fertilizer powder. It has each of the nutrients plants have to thrive and it's rich in organic matter. The NPK profile of cow dung is 1% potassium, 4% nitrogen, and 2% phosphorous. The other constitutes of cow dung besides micronutrients and organic matter are various enzymes and microorganisms. To be able to convert cow dung into fertilizer, specialized machines are often needed. The fertilizer produced can vastly improve soil structure and fertility. What's more, the fertilizer can promote healthy microbial growth and stop common root diseases and rot.

Cow manure is a great organic fertilizer, but if you set fresh cow dung on the soil, the huge amounts of ammonia produced could cause a horrible odor and burn crops. Additionally, unprocessed cow dung might be full of salt, dependant upon the diet the cattle were fed, which can be not ideal for crop growth. To generate a nutritious fertilizer, cow dung has to be composed. Natural fermentation of cow dung can take a long time, but fortunately, there is now a variety of modern composting machinery available on the market made to speed up the process.

Cow dung should be fully fermented before it is actually used on agricultural soil. Otherwise, it would cause soil temperatures to enhance, which could damage crop root systems. Furthermore, fresh cow dung is full of viruses and pathogens, which may be damaging to the surrounding environment and water supplies.

To turn cow manure right into a safe organic NPK powder fertilizer, it needs to be fully decomposed. The easiest way to compost cattle waste is to invest in the very best cow dung fertilizer machines, like self-propelled compost turners, hydraulic windrow turners, and dewatering machines.

High-grade NPK compound fertilizer is on the go which is relatively cheap to generate. By producing powder fertilizer from cow dung, you can help to handle the mounting global environmental pollution problems associated with mounting animal waste. What's more, together with the right equipment, powder fertilizer may be processed further into granules or pellets. Granules are easier to store and transport. Browse the latest granulation machines to finish your cow dung fertilizer production line.

Thursday, 13 February 2020

How to dewater cow dung?

A Good Look In The Cow Dung Dewatering Machine & Its Role For Making Cow Dung Compost

If you would like make the most from cow dung, then it is best to create cow dung manure. Basically, by composting the cow dung, the microorganisms will naturally disintegrate every one of the organic matter from the dung. A lot of heat will be released which can kill any eggs, pathogens and seeds within the cow dung. There are lots of steps with regards to turning cow dung into compost and you will have to prepare a variety of raw materials, develop a compost pile and after that transform it. Within the raw materials, you need to manage the liquid content and also add sawdust and straw as a way to control the C/N ratio. After cow dung is converted into compost, this can then be used to make fertilizer. We are going to now take a closer look at the initial step of producing cow dung compost that will call for a dewatering machine.

This type of water content from the cow dung is an extremely important aspect when making cow dung compost as it might potentially hamper the entire process of composting as well as its overall quality. When you don't know already, fresh cow dung from cows typically has 80% water content. However, a water content of 50 - 60% is required for the composting process. For that reason, a cow dung dewatering machine is essential as a way to remove several of the water through the cow dung. When this machine is commonly used to dewater the cow dung, it will become loosened which prevents caking which happens to be important for the compost process. Utilizing a cow dung dewatering machine, it is simple to remove water when necessary to make the best quality compost.

There are actually typically two different kinds of cow dung dewatering machines and they range from the inclined screen separator machine as well as the solid liquid separator machine. Both of these machines try to remove water from cow dung through squeezing it. This type of water that is certainly separated in the cow dung can actually be used to make biogas and even liquid fertilizer. In terms of the dewatering machines, the parts which come into connection with the cow dung to squeeze it are usually made out of 304 steel. It is a very strong steel that is highly immune to corrosion. However, if you would like make the most of your dewatering machine, it is essential that you clean the screen in particular after using it. A large number of dewatering machines are unable to only assist cow dung, but can also be used to dewater pig manure, chicken manure as well as other animal waste.

Having said that, there are several more elements of creating cow dung compost that ought to be considered as well as the dewatering machine. This machine is just one step and you also have to add other materials towards the dung for example rice hull, straw and even saw dust. The cow dung will then have to be composted either using windrow composting, fermentation grooves or maybe in a fermentation tank. So, if you're considering making cow dung compost, be sure you keep learning and researching the process in order to eventually master each step.

If you would like make the most from cow dung, then it is best to create cow dung manure. Basically, by composting the cow dung, the microorganisms will naturally disintegrate every one of the organic matter from the dung. A lot of heat will be released which can kill any eggs, pathogens and seeds within the cow dung. There are lots of steps with regards to turning cow dung into compost and you will have to prepare a variety of raw materials, develop a compost pile and after that transform it. Within the raw materials, you need to manage the liquid content and also add sawdust and straw as a way to control the C/N ratio. After cow dung is converted into compost, this can then be used to make fertilizer. We are going to now take a closer look at the initial step of producing cow dung compost that will call for a dewatering machine.

This type of water content from the cow dung is an extremely important aspect when making cow dung compost as it might potentially hamper the entire process of composting as well as its overall quality. When you don't know already, fresh cow dung from cows typically has 80% water content. However, a water content of 50 - 60% is required for the composting process. For that reason, a cow dung dewatering machine is essential as a way to remove several of the water through the cow dung. When this machine is commonly used to dewater the cow dung, it will become loosened which prevents caking which happens to be important for the compost process. Utilizing a cow dung dewatering machine, it is simple to remove water when necessary to make the best quality compost.

There are actually typically two different kinds of cow dung dewatering machines and they range from the inclined screen separator machine as well as the solid liquid separator machine. Both of these machines try to remove water from cow dung through squeezing it. This type of water that is certainly separated in the cow dung can actually be used to make biogas and even liquid fertilizer. In terms of the dewatering machines, the parts which come into connection with the cow dung to squeeze it are usually made out of 304 steel. It is a very strong steel that is highly immune to corrosion. However, if you would like make the most of your dewatering machine, it is essential that you clean the screen in particular after using it. A large number of dewatering machines are unable to only assist cow dung, but can also be used to dewater pig manure, chicken manure as well as other animal waste.

Having said that, there are several more elements of creating cow dung compost that ought to be considered as well as the dewatering machine. This machine is just one step and you also have to add other materials towards the dung for example rice hull, straw and even saw dust. The cow dung will then have to be composted either using windrow composting, fermentation grooves or maybe in a fermentation tank. So, if you're considering making cow dung compost, be sure you keep learning and researching the process in order to eventually master each step.

Saturday, 8 February 2020

Why Most People Choose Compost Windrow Turner?

Composting is among the most reliable processes that takes care of your organic waste in your farm. Plus it essentially provides your flower plants and vegetables with all the nutrients which they readily necessity for healthy growth. However, one of the many things you'll ever use during the composting process can be a compost windrow turner. Our article features the benefits of by using a compost windrow turner for the composting project.

Compost windrow turners happen to be reported to be quite reliable, exceptionally long service life in addition to extremely efficient and pretty low maintenance. They also have been considered to be extra hardened to support operations and they also even have a set of completely replaceable steel blades. However, the steel blades were positioned to the drum to ensure that the types of materials added were completely blended. And once we say completely blended, we mean that each portion of the mixture was properly blended all the way to the windrows base.

During the process, the materials on the outer ends are brought to the middle wherein a peak is created as the material travels through the bottom to the top level. However, this creates the same effect that way of the chimney and yes it proceeds allowing both oxygen and CO2 to flow. And if you're looking for technical support, all of that might be provided in the windrow turner manufacturer you'll be given database calculations, consultations, monitoring, as well as online batch tracking for the projects.

If you've ever composted before, you're already gonna realize that as soon as your pile is permitted to breathe, the composting process becomes considerably more efficient. So, it's best to turn in and open building that allows a lot more being exposed to air. And it's wise to also keep in mind that only if subjected to enough oxygen will your microbe activity increase. Hence, you should ensure you turn your windrow.

When it comes to the quantity to times that you turn, you're gonna should monitor the conditions. So, be sure you consider the temperature with a temperature probe. However, you're gonna need to turn your pile a little more to actually activate the wearing down process successfully. Within the space of 2 weeks, your pile will require a lot less turning because the max temperature would have already been reached.

Should your process was really a complete success, you're end product will likely be of the best. And you'll get a rich high-quality product expecting you just a place of six or seven weeks. Whenever your process is useful and efficient, you're likely to reap be benefits associated with not just a high product but additionally a safer product for your environment. Plus your surrounding can also be cleaner.

While we conclude we have now just investigated the numerous advantages that come if you use the compost windrow turner. And that we have discussed some key elements in the process. So, don't forget your turner is premium quality, consistent, generates a pathogen free product, they are able to endure a few of the toughest weather conditions and are generally extremely effective.

Compost windrow turners happen to be reported to be quite reliable, exceptionally long service life in addition to extremely efficient and pretty low maintenance. They also have been considered to be extra hardened to support operations and they also even have a set of completely replaceable steel blades. However, the steel blades were positioned to the drum to ensure that the types of materials added were completely blended. And once we say completely blended, we mean that each portion of the mixture was properly blended all the way to the windrows base.

During the process, the materials on the outer ends are brought to the middle wherein a peak is created as the material travels through the bottom to the top level. However, this creates the same effect that way of the chimney and yes it proceeds allowing both oxygen and CO2 to flow. And if you're looking for technical support, all of that might be provided in the windrow turner manufacturer you'll be given database calculations, consultations, monitoring, as well as online batch tracking for the projects.

If you've ever composted before, you're already gonna realize that as soon as your pile is permitted to breathe, the composting process becomes considerably more efficient. So, it's best to turn in and open building that allows a lot more being exposed to air. And it's wise to also keep in mind that only if subjected to enough oxygen will your microbe activity increase. Hence, you should ensure you turn your windrow.

When it comes to the quantity to times that you turn, you're gonna should monitor the conditions. So, be sure you consider the temperature with a temperature probe. However, you're gonna need to turn your pile a little more to actually activate the wearing down process successfully. Within the space of 2 weeks, your pile will require a lot less turning because the max temperature would have already been reached.

Should your process was really a complete success, you're end product will likely be of the best. And you'll get a rich high-quality product expecting you just a place of six or seven weeks. Whenever your process is useful and efficient, you're likely to reap be benefits associated with not just a high product but additionally a safer product for your environment. Plus your surrounding can also be cleaner.

While we conclude we have now just investigated the numerous advantages that come if you use the compost windrow turner. And that we have discussed some key elements in the process. So, don't forget your turner is premium quality, consistent, generates a pathogen free product, they are able to endure a few of the toughest weather conditions and are generally extremely effective.

Friday, 7 February 2020

Top Three Strategies To Make Organic Fertilizer

If you're looking for the ideal mix of organic fertilizer, you are able to literally whip your own by incorporating simply ingredients from around your house. Organic fertilizers can be simply made out of numerous things found like banana peels, egg shells and even coffee grounds for example. Our article features among the best ways to help make your own organic fertilizer.

First off, we'll examine banana peels.

Consuming a good serving of banana can greatly assist and it will surely even boost some of the potassium that you've lost. And you also know who else can be helped by a little extra added potassium, your roses can. So, you can just place in a peel or two burying them under some mulch to ensure these people to compost and before you realize it, you'll have considerably more blooms.

Second is the use of coffee grounds.

If you've got plants that thrive on some extra acid such as azaleas, tomatoes, roses and in many cases blueberries, you can include some coffee grounds to the soil. You can simply sprinkle or perhaps mix up a batch of coffee and water and pour it like if you were watering your plants. Quickly enough you'll watch your plants flourishing far more than before.

Next is using egg shells.

However, you'll need to make certain that these are clean so be sure you wash them before crushing them. Then all you'll need to do is mix them in the soil if you've got peppers or even tomatoes. Using this type of, you'll be helping to prevent blossom end rot and you'll soon have some really beautiful fruits you could even save for seed keeping.

You may even make fertilizer from seaweed and you don't must wash them before using them. And both fresh and dried can be employed for your soil and your plants. You'll simply must soak some chopped seaweed in some water for a couple weeks and after that you'll have the capacity to make use of it drench your foliage and soil. Additionally, you can even test out seaweed and blend it with several various tea fertilizers.

Of course, if you're growing some weeds in your garden, we're here to tell you that you're already growing the ideal mixture of fertilizers. Yellow dock, horsetail, nettles as well as chickweed just for example are great for home made fertilizers. And to make usage of them, you'll simply want to make a compost pile and add several of the dried weeds into it.

If you've already got a healthy compost pile and you're simply planning to enhance your beneficial bacteria and microbes, you can easily use molasses. You'll should mix in close proximity to 3 tablespoons in a gallon water. And as time progresses, start watering your plants with them.

Since we conclude, we certainly have just considered some pretty interesting and proven strategies to make organic fertilizers. While adding ferts, also you can experiment as time passes and even build your own special blend. However, make sure to exercise safety when performing activities.

First off, we'll examine banana peels.

Consuming a good serving of banana can greatly assist and it will surely even boost some of the potassium that you've lost. And you also know who else can be helped by a little extra added potassium, your roses can. So, you can just place in a peel or two burying them under some mulch to ensure these people to compost and before you realize it, you'll have considerably more blooms.

Second is the use of coffee grounds.

If you've got plants that thrive on some extra acid such as azaleas, tomatoes, roses and in many cases blueberries, you can include some coffee grounds to the soil. You can simply sprinkle or perhaps mix up a batch of coffee and water and pour it like if you were watering your plants. Quickly enough you'll watch your plants flourishing far more than before.

Next is using egg shells.

However, you'll need to make certain that these are clean so be sure you wash them before crushing them. Then all you'll need to do is mix them in the soil if you've got peppers or even tomatoes. Using this type of, you'll be helping to prevent blossom end rot and you'll soon have some really beautiful fruits you could even save for seed keeping.

You may even make fertilizer from seaweed and you don't must wash them before using them. And both fresh and dried can be employed for your soil and your plants. You'll simply must soak some chopped seaweed in some water for a couple weeks and after that you'll have the capacity to make use of it drench your foliage and soil. Additionally, you can even test out seaweed and blend it with several various tea fertilizers.

Of course, if you're growing some weeds in your garden, we're here to tell you that you're already growing the ideal mixture of fertilizers. Yellow dock, horsetail, nettles as well as chickweed just for example are great for home made fertilizers. And to make usage of them, you'll simply want to make a compost pile and add several of the dried weeds into it.

If you've already got a healthy compost pile and you're simply planning to enhance your beneficial bacteria and microbes, you can easily use molasses. You'll should mix in close proximity to 3 tablespoons in a gallon water. And as time progresses, start watering your plants with them.

Since we conclude, we certainly have just considered some pretty interesting and proven strategies to make organic fertilizers. While adding ferts, also you can experiment as time passes and even build your own special blend. However, make sure to exercise safety when performing activities.

Subscribe to:

Comments (Atom)