Fertilizer blocking problems usually occur in the process of fertilizer processing, storage and transportation, and are caused by the absorption, dissolution, evaporation and recrystallization of fertilizer particles. In this process, a crystal bridge is formed, causing small particles to form large particles and clump.

So how to avoid the fertilizer clumps generated by NPK fertilization equipment?

1. Choose the right raw material.

Fertilizer production of raw materials, such as ammonium salts, phosphates, trace element salts, potassium salts, etc., mostly contain crystalline water, easy to absorb water, such as ammonium sulfate, phosphate, trace elements easy to reunite, insoluble in water. Urea is prone to extract water and clumps with trace element salts.

Choose raw materials that are not easy to clump and produce fertilizer that does not clump. For example, fertilizers with humic acid as the main raw material and amino acids as the main raw materials are not easy to clump. Also, try to keep the material dry when selecting it.

2. When producing NPK fertilizer, the water content and packaging temperature of the fertilizer should be reduced and the appropriate production time should be selected.

Fertilizer production is generally non-closed. During the production process, the greater the air humidity, the easier the fertilizer is to absorb moisture clumps. Fertilizer production avoids the rainy season and concentrates on fertilizer production on dry days. In the fertilizer production process, the raw material is heated by dryer, so that the water content of fertilizer is controlled at 0.6%, prolonging the cooling time of fertilizer, reducing the packing temperature, making the fertilizer not easy to clump.

3. Add anti-clumping agent to reduce the physical chemical reaction between NPK fertilizer particles.

The higher the room temperature, the easier it is to dissolve. In general, raw materials dissolve in their own crystalline water and cause clumps. Adding talcum powder, humic acid and other non-clumping powders can also be added some surfactants to prevent clumps.

4. Reduce the height of the fertilizer stacking and storage pressure.

The greater the external pressure of fertilizer, the easier it is for the crystal to clump in contact with the crystal, and the smaller the external pressure, the more difficult it is to clump.

5. The NPK fertilizer can be screened with a screening machine to further improve the uniformity of fertilizer particles.

NPK fertilizer particle size is not uniform, particle spacing is small, contact area is large, easy to reunite. If the pressure strength of fertilizer particles is low, deformation and breakage are easily occurred during packaging, transportation and storage, increasing the contact area between the particles, which can also lead to fertilizer clumps.

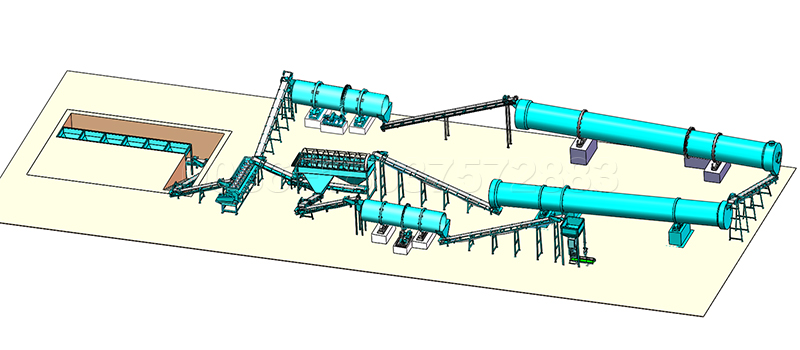

If the fertilizer plant uses NPK fertilizer production line to produce a large amount of fertilizer, can be used for two screening machines to obtain suitable fertilizer particles.

6. Production of NPK fertilizer particles.

Because of the small contact area between circular particles, it is not easy to crystallize the clumps. Therefore, the granulation of nitrogen and phosphorus potassium fertilizer is beneficial to the storage, transportation and fertilization of fertilizer.

When using roller granulators to produce NPK compound fertilizer particles, the dryer is not used, but the raw materials for the production of fertilizer must have good adhesion.

When producing NPK compounding particles with a disc granulator (or drum granulator), it must be dried and cooled.

No comments:

Post a Comment