Organic fertilizer and compound fertilizer produced by organic fertilizer production line can be used in agriculture. Bio organic fertilizer is a new type of organic fertilizer, which will also be produced and used in agriculture through bio fertilizer manufacturing technology. Agriculture. Why do we use bio organic fertilizer?

Introduction of bio organic fertilizer

Bio organic fertilizer refers to microbial (bacterial) fertilizer, referred to as bacterial fertilizer, also known as microbial inoculant. It is produced by microbial fermentation, with specific efficacy, and contains a large number of beneficial microorganisms. It can fix nitrogen in the air or active nutrients in the soil, improve the nutrient environment of plants, or produce living substances in the life activities of microorganisms, so as to stimulate the growth of specific microorganisms in plants. Biological fertilizer, chemical fertilizer and organic fertilizer are important sources of fertilizer in agricultural production.

Function of biological fertilizer:

We can use biofertilizer production lines to produce bio organic fertilizer granulators. What is the function of biological fertilizer?

1. Improve soil fertility. This is the main function of biological fertilizer. For example, all kinds of autogenous, combined or symbiotic nitrogen fixation biological fertilizers can fix nitrogen in the air and increase the nitrogen content in the soil; microorganisms that decompose phosphorus and potassium minerals, such as silicate bacteria, can decompose feldspar, potassium, mica and phosphate rock in the soil, so as to make insoluble phosphorus and potassium effective.

2. Make and assist crops to absorb nutrients. Some bacterial fertilizers can not only increase the effective nutrients of soil, but also produce a variety of hormones and vitamins, thus promoting the growth of crops.

3. Enhance plant resistance. After inoculated with some biological fertilizers, they become the main bacteria in the rhizosphere of crops because of their massive reproduction in the roots. They can secrete antibiotics against fungi and bacteria, so they live in the growth of hyperactive bacteria.

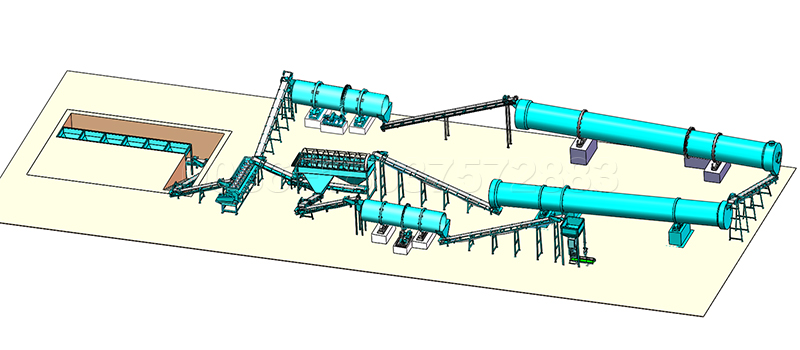

Main fertilizer equipment for biological fertilizer production line from sx line mx:

In the bio organic fertilizer production line, there are different types of fertilizer equipment to complete the production process of bio fertilizer. It is equipped with fermentation compost turning machine, fertilizer mixer, fertilizer crusher and fertilizer granulator. Each series of fertilizer machines are designed for different types and models. Like fertilizer granulator, in the production line of biological fertilizer, we can use disc granulator to produce biological organic fertilizer granulator. Sometimes, drum granulator can also be used to produce biological organic fertilizer granulator. This type of fertilizer granulator is usually used in the production process of NPK fertilizer. Detailed info to start a bio fertilizer plant project, welcome go to https://organicfertilizerproductionline.com/bio-fertilizer-plant-project/