Poultry farms tend to have a lot of waste being generated on a daily basis. However, by using a poultry composting machine you're going so that you can turn your poultry waste in to a profit. And each of you can do this inside of every week. Our article features the poultry composting machine as well as the various benefits that this provides for investors.

When poultry waste is composted, your end item is free from foul odors, harmful pathogens and it is extremely clean. And you'll have the capacity to use it is an additive for your plants. During the process, everything that is really needed is actually a suitable yet sufficient volume of dry carbon. These may include sawdust, straw and various other carbon sources.

The top manufacturer has created an insulating poultry composter which creates the perfect environment for deteriorating the organic matter used. And yes it even ensures that the insulation retains enough heat. Heat is one of the most critical factors that is required for the composting process to become a complete success. And yes it even speeds up the complete process resulting in a more effective turnover.

Moreover, as the drum is turned, the fabric beings to enjoy a air flow. Aeration is likewise important for the composting process since it ensure that the temperature goes to the optimum temperature right away. Hence, the many aerobic microbes will be in the right environment.

Once you actually turn your poultry composting machine, it is going on to mix the carbon source as well as the types of materials are composted during the process. It goes on to make certain that there are also no spots that are left cold. Hence the procedure goes smoothly. Additionally, the entire process and machine creates a number of benefits for anybody who invests within it.

Money is a large factor within any industry and lots of cash is saved during this process. This is simply because that you'll be saving on labor cost, in addition to fuel as you don't need any for that process to start. Along with the poultry composting machines also come with a guaranteed long service life due to way they were constructed.

Composting your poultry waste even improves your general biosecurity. Once you compost your materials, you reduce the quantity of rodents, wild birds and in many cases scavengers that can come looking for something to enjoy. And you'll also be able to finally not need to worry about the neighbors dog which comes due to the range of scents.

You'll also stay away from on the vehicular traffic that can occur due to service vehicles coming to collect waste products. Disease causing pathogens may also be going to be destroyed and you'll also be able to dump things pretty quickly. In addition, the overall expertise of the environment is also improved.

Boosting the environment is amongst the greatest things that you could have performed. And each of this is certainly mainly because that fuel isn't burned and there's the opportunity that you won't need to light fires too frequently to manage organic waste. Additionally, getting rid of these materials have to have the least energy.

When we conclude, we now have just checked out the poultry composting machine. And that we have likewise checked out the main benefits which come as a result. However, it's best to bear in mind that you simply shouldn't handle any sort of waste without a pair of gloves.

Compost Making Tech, introduces you all the leading compost production technologies, facilities, formulars you want to know

Sunday, 31 May 2020

Friday, 29 May 2020

Goat Manure Composting Process

Compost fertilizers are safe and efficient, so there's not surprising a lot of farmers prefer them to other products. Besides, turning animal manure into organic fertilizer is a good strategy to reuse waste. Apparently, goat manure is probably the best substances to fertilize crops, as it doesn't attract insects or burn plants like cow or horse manure. If you want to know how to turn your goat manure into compost fertilizer, you've come to the right place. This informative article will show you one of the best methods.

It is important when composting goat manure would be to closely watch the moisture, the temperature and also the oxygen content of your raw matter. As composting occurs on account of the action of microorganisms that consumer oxygen and water, you have to ensure that they have an optimal environment for doing their job. Temperature regulation is particularly important, since a too much temperature may damage these microorganisms. SX Goat Manure Compost Machine can solve this tepmerature system by working.

The most efficient method to turn goat manure into compost fertilizer is to apply a compost turner for fermentation. In the first place, you'll should prepare the raw material for composting. If you choose to add various auxiliaries, you have to mix them in the manure and place the combination into fermentation grooves. You can even pile these matters up in rows. If you decide to use grooves, be sure that the height of your organic waste doesn't exceed the height of your groove. Detailed info on groove composting tech, you can go to https://compostturnermachine.com/groove-composting/

Once you've done each one of these, you should try to regularly turn the compost pile through the entire entire fermentation process. This isn't always easy. Inside the first week, you'll need to turn the compost several times each day. Right after the first week, turning the organic waste once every two days should be enough to have good quality compost fertilizer.

The efficiency of the process depends on the compost turner. This pieces of equipment ought to be as economical so when efficient as possible. That is why you have to be cautious while you shop around to get the best machine. Always inform yourself on all details prior to your choice. For example, a windrow compost turner could be either the self-propelled type or maybe the crawler type. Whatever your decision, you'll only need an individual to use the device. These machines run on Diesel oil and are generally ideal for goat farm manure treatment. There's also a different type of machine, the groove compost turner. This piece of equipment comes with a stirring mechanism that turns the compost even though the machine moves alongside the walls from the groove. Electrically controlled, this gadget requires just one operator to check the procedure.

Whenever you run a goat farm, odds are your manure processing needs and much beyond the requirements of a house owner who just has a number of goats. For those who have multiple grooves, you may even want a transfer machine, to use exactly the same compost turning device on all of them. This is usually a very efficient way to turn huge volumes of goat manure into fertilizer.

It is important when composting goat manure would be to closely watch the moisture, the temperature and also the oxygen content of your raw matter. As composting occurs on account of the action of microorganisms that consumer oxygen and water, you have to ensure that they have an optimal environment for doing their job. Temperature regulation is particularly important, since a too much temperature may damage these microorganisms. SX Goat Manure Compost Machine can solve this tepmerature system by working.

The most efficient method to turn goat manure into compost fertilizer is to apply a compost turner for fermentation. In the first place, you'll should prepare the raw material for composting. If you choose to add various auxiliaries, you have to mix them in the manure and place the combination into fermentation grooves. You can even pile these matters up in rows. If you decide to use grooves, be sure that the height of your organic waste doesn't exceed the height of your groove. Detailed info on groove composting tech, you can go to https://compostturnermachine.com/groove-composting/

Once you've done each one of these, you should try to regularly turn the compost pile through the entire entire fermentation process. This isn't always easy. Inside the first week, you'll need to turn the compost several times each day. Right after the first week, turning the organic waste once every two days should be enough to have good quality compost fertilizer.

The efficiency of the process depends on the compost turner. This pieces of equipment ought to be as economical so when efficient as possible. That is why you have to be cautious while you shop around to get the best machine. Always inform yourself on all details prior to your choice. For example, a windrow compost turner could be either the self-propelled type or maybe the crawler type. Whatever your decision, you'll only need an individual to use the device. These machines run on Diesel oil and are generally ideal for goat farm manure treatment. There's also a different type of machine, the groove compost turner. This piece of equipment comes with a stirring mechanism that turns the compost even though the machine moves alongside the walls from the groove. Electrically controlled, this gadget requires just one operator to check the procedure.

Whenever you run a goat farm, odds are your manure processing needs and much beyond the requirements of a house owner who just has a number of goats. For those who have multiple grooves, you may even want a transfer machine, to use exactly the same compost turning device on all of them. This is usually a very efficient way to turn huge volumes of goat manure into fertilizer.

Thursday, 28 May 2020

Compost Equipment Purchasing Tips

What You Should Note When Buying A Compost Fertilizer Making Machine

Being able to turn waste into a fertilizer can be incredibly valuable, especially if you have a garden. With that said, you'll want to make sure that the compost fertilizer making machine you purchase is a good fit for your needs. These are a few of the factors you'll want to look for when considering different machines on the market.

Electric Composters Can Be A Great Investment

It can take time to turn compost into usable fertilizer. However, you'll be able to automate the process if you choose to buy an electric composter. These devices are able to process organic matter, turning it into a fertilizer or a soil conditioner.

In some cases, an electric composter will add other substances to the fertilizer as well, such as humus and humus acids. If you don't feel like you have the patience for composting, a machine like this should be a great purchase for you.

Consider A Composter That's Small Enough To Fit Into Your Kitchen

You'll want to make sure you're able to quickly add the food waste you produce to your composter. Because of this, you might want to select a smaller composter that's small enough to be stored in your kitchen. If you buy a small composter, you may be able to store it beneath your sink or underneath your kitchen cabinets.

A small composter won't be ideal for all consumers. If you produce a great deal of food waste, or if you're interested in a composter that you can use in a commercial building, you'll want to explore other options. However, if the things listed above aren't true for you, you should strongly consider something that's on the small side.

Read Reviews Before You Buy

Before you invest in a fertilizer-making machine, you'll want to make sure you have a clear picture of what it is you're buying. In addition to reading the product description carefully, you should take a close look at any reviews that you might find.

Reviews can help you to determine whether or not a product is worth the money. Reviewers will often point out potential problems that you wouldn't have been aware of otherwise. A reviewer may also offer you tips that will help you to use your new composter more effectively.

Find A Machine That Will Work With The Type Of Waste That You Produce

Not all composting machines are compatible with all types of waste. As an example, if you want to be able to compost your coffee grounds or chicken or fish bones, you'll need to look for a machine that is capable of handling that. Take the time to evaluate machines so that you can determine whether or not they'll work for you.

Keep all of these tips in mind if you're in the market for a compost fertilizer making machine. As long as you know what to look out for, you should be able to find a machine that you can reliably use to make fertilizer. You'll be able to reduce the amount of waste you produce and create something that you can actually use.

Being able to turn waste into a fertilizer can be incredibly valuable, especially if you have a garden. With that said, you'll want to make sure that the compost fertilizer making machine you purchase is a good fit for your needs. These are a few of the factors you'll want to look for when considering different machines on the market.

Electric Composters Can Be A Great Investment

It can take time to turn compost into usable fertilizer. However, you'll be able to automate the process if you choose to buy an electric composter. These devices are able to process organic matter, turning it into a fertilizer or a soil conditioner.

In some cases, an electric composter will add other substances to the fertilizer as well, such as humus and humus acids. If you don't feel like you have the patience for composting, a machine like this should be a great purchase for you.

Consider A Composter That's Small Enough To Fit Into Your Kitchen

You'll want to make sure you're able to quickly add the food waste you produce to your composter. Because of this, you might want to select a smaller composter that's small enough to be stored in your kitchen. If you buy a small composter, you may be able to store it beneath your sink or underneath your kitchen cabinets.

A small composter won't be ideal for all consumers. If you produce a great deal of food waste, or if you're interested in a composter that you can use in a commercial building, you'll want to explore other options. However, if the things listed above aren't true for you, you should strongly consider something that's on the small side.

Read Reviews Before You Buy

Before you invest in a fertilizer-making machine, you'll want to make sure you have a clear picture of what it is you're buying. In addition to reading the product description carefully, you should take a close look at any reviews that you might find.

Reviews can help you to determine whether or not a product is worth the money. Reviewers will often point out potential problems that you wouldn't have been aware of otherwise. A reviewer may also offer you tips that will help you to use your new composter more effectively.

Find A Machine That Will Work With The Type Of Waste That You Produce

Not all composting machines are compatible with all types of waste. As an example, if you want to be able to compost your coffee grounds or chicken or fish bones, you'll need to look for a machine that is capable of handling that. Take the time to evaluate machines so that you can determine whether or not they'll work for you.

Keep all of these tips in mind if you're in the market for a compost fertilizer making machine. As long as you know what to look out for, you should be able to find a machine that you can reliably use to make fertilizer. You'll be able to reduce the amount of waste you produce and create something that you can actually use.

Tuesday, 26 May 2020

Compost Powder Making

What Role Does A Fertilizer Crusher Play Inside The Fertilizer Production Line?

A fertilizer crusher is among one of those investments people don't even think about when they are studying the available options looking at them. They attempt to complement something which will add value to their production line and that is certainly when the idea of a fertilizer crusher enters into the equation.

Listed here are the key reasons to choose a fertilizer crusher and why it is a must for your production line. Without having this your sleeve, the outcomes aren't gonna be as you desire and that is going to hold you back across the long term.

Get started with a fertilizer crusher right away and this is why.

Increased Crushing of Organic Waste

It starts off with the overall purpose of a fertilizer crusher, which is to handle organic waste. When organic waste is certainly going from the production line, it will be in the original state, which isn't something you would like to deal with. As a result, you might want a specialized machine that will manage the organic waste and be sure it is actually crushed as intended.

Consequently, designers have got enough time to make the fertilizer crusher mainly because it simplifies the method and speeds things up immediately. This enables the development line to move along with a reasonable speed which is consistent with modern business goals.

Improved Composting

Composting is definitely the goal and that is why you have to take the time to understand the need for a great fertilizer crusher. It will likely be a machine that is a game-changer for your personal setup and will probably consistently power amazing results as soon as it is established. You are likely to know it continues to work well and will be a significant accessory for your overall production line. The crushing will probably be done regardless of the waste that is certainly coming through.

Streamlined Results

One of the many responsibilities of the fertilizer crusher is to make certain the final results are streamlined. Otherwise, the organic waste that is certainly being pushed through won't get to the state it must be in. This really is a concern a lot of people have when they are looking to analyze exactly what a fertilizer crusher can do with regard to their setup and why it's this sort of advantageous investment advancing. The objective remains to choose something that is fully consistent with what the operation needs and it starts by getting the fertilizer crusher all set to go.

These are the basic main benefits that come along with an advanced fertilizer crusher after it is placed into a fertilizer production line. It is one of the best investments an individual can make in terms of their overall setup and ensuring it is heading in the right direction. The fertilizer crusher will probably speed things up without delay and is going to push the organic waste for the desired state faster than in the past. This is certainly essential for individuals who desire to make certain they are trending from the right direction. More info about crushers used in composting, welcome to https://compostturnermachine.com/compost-crusher/

A fertilizer crusher is among one of those investments people don't even think about when they are studying the available options looking at them. They attempt to complement something which will add value to their production line and that is certainly when the idea of a fertilizer crusher enters into the equation.

Listed here are the key reasons to choose a fertilizer crusher and why it is a must for your production line. Without having this your sleeve, the outcomes aren't gonna be as you desire and that is going to hold you back across the long term.

Get started with a fertilizer crusher right away and this is why.

Increased Crushing of Organic Waste

It starts off with the overall purpose of a fertilizer crusher, which is to handle organic waste. When organic waste is certainly going from the production line, it will be in the original state, which isn't something you would like to deal with. As a result, you might want a specialized machine that will manage the organic waste and be sure it is actually crushed as intended.

Consequently, designers have got enough time to make the fertilizer crusher mainly because it simplifies the method and speeds things up immediately. This enables the development line to move along with a reasonable speed which is consistent with modern business goals.

Improved Composting

Composting is definitely the goal and that is why you have to take the time to understand the need for a great fertilizer crusher. It will likely be a machine that is a game-changer for your personal setup and will probably consistently power amazing results as soon as it is established. You are likely to know it continues to work well and will be a significant accessory for your overall production line. The crushing will probably be done regardless of the waste that is certainly coming through.

Streamlined Results

One of the many responsibilities of the fertilizer crusher is to make certain the final results are streamlined. Otherwise, the organic waste that is certainly being pushed through won't get to the state it must be in. This really is a concern a lot of people have when they are looking to analyze exactly what a fertilizer crusher can do with regard to their setup and why it's this sort of advantageous investment advancing. The objective remains to choose something that is fully consistent with what the operation needs and it starts by getting the fertilizer crusher all set to go.

These are the basic main benefits that come along with an advanced fertilizer crusher after it is placed into a fertilizer production line. It is one of the best investments an individual can make in terms of their overall setup and ensuring it is heading in the right direction. The fertilizer crusher will probably speed things up without delay and is going to push the organic waste for the desired state faster than in the past. This is certainly essential for individuals who desire to make certain they are trending from the right direction. More info about crushers used in composting, welcome to https://compostturnermachine.com/compost-crusher/

Saturday, 23 May 2020

Make Fertilizer Outof Cow Dung

Finding Out How To Make Use Of A Cow Dung Fertilizer Machine To Transform Cow Dung Into Fertilizer

Cow dung is a great way to obtain raw material when you make organic fertilizers. There are a lot of farmers, however, who don’t discover how to handle the cow dung. Several farmers utilize this fresh cow dung as fertilizers by applying them right to their crops. If fresh cow dung gets applied directly, it may well bring injury to the crops because of presence of harmful elements in the manure, and may also even lead to pollution. Therefore, you ought to look for a cow dung fertilizer that can eliminate every one of these problems.

There are many complete fertilizer making machines available, together with a variety of specifications and types of machines for your choosing. With the aid of these appliances, you should make organic fertilizer faster and much more conveniently. What’s more, the cow dung manure produced will probably be healthier and fertile. If you’re considering to help make cow dung organic manure, you’ll have two fertilizer production lines to decide on. You could make both pellets fertilizer and cow dung powder fertilizer.

Cow Dung Powdery Fertilizer Making Line

If you want to make cow dung manure powder, there are many equipment recommendations for you to consider:

- Dewatering screw press machine. When you make compost, it’s necessary to experience a dewatering machine. Through this piece of equipment, the solid cow manure are often more convenient to transport. What’s more, you can even sell the cow dung manure directly or apply it for creating organic fertilizers.

- Cow dung powder making machine. By equipping yourself with powder making machine, you ought to obtain fine cow dung manure powder. A vertical crusher and a semi-wet material crushing machine are an outstanding option to pulverizing animal manures.

- Small-scale compost turner. A compost turning machine is a fundamental cow dung processing equipment. With the aid of a turning machine, you’ll have much less time for composting. Simultaneously, the labor force will probably be significantly reduced.

Since fresh cow dung contains high moisture, you should dry it first before composting. The cow drying machine can help you get both solid and liquid cow dung manure. It utilizes screw press force to separate the liquid from the available materials. While you collect the solid, the liquid must be discharged using the pump such you could fertilize them into your plants directly.

Just How Do Cow Dung Fertilizer Machines Work with Making Cow Dung to Fertilizer Granules?

When making cow dung fertilizer granules, it’s an absolute necessity to covert the fertilizer powders into fine fertilizer pellets. Aside from the fertilizer powder making machine, you additionally need a fertilizer pellet equipment, drier, cooler, coating machine, and screening equipment. Just how do these appliances make powder into fertilizer pellets?

- Cow dung granulating. A granulator is mostly used for converting powders into pellets. Afterward, it is possible to feed them in to the pellet making machine.

- Drying and cooling. Ever since the granulator makes pellets in extremely high temperatures and implements wet granulation techniques, the finished granules are humid and heated. The drying machine, as well as the cooling machine, will be more convenient in using to create fertilizer pellets.

- Pellets screening. Separate unqualified pellets from the specific products by using rotating screening equipment.

- Quality products coating. By coating the fertilizer granular, it raises the pellets’ physical properties.

Cow dung is a great way to obtain raw material when you make organic fertilizers. There are a lot of farmers, however, who don’t discover how to handle the cow dung. Several farmers utilize this fresh cow dung as fertilizers by applying them right to their crops. If fresh cow dung gets applied directly, it may well bring injury to the crops because of presence of harmful elements in the manure, and may also even lead to pollution. Therefore, you ought to look for a cow dung fertilizer that can eliminate every one of these problems.

There are many complete fertilizer making machines available, together with a variety of specifications and types of machines for your choosing. With the aid of these appliances, you should make organic fertilizer faster and much more conveniently. What’s more, the cow dung manure produced will probably be healthier and fertile. If you’re considering to help make cow dung organic manure, you’ll have two fertilizer production lines to decide on. You could make both pellets fertilizer and cow dung powder fertilizer.

Cow Dung Powdery Fertilizer Making Line

If you want to make cow dung manure powder, there are many equipment recommendations for you to consider:

- Dewatering screw press machine. When you make compost, it’s necessary to experience a dewatering machine. Through this piece of equipment, the solid cow manure are often more convenient to transport. What’s more, you can even sell the cow dung manure directly or apply it for creating organic fertilizers.

- Cow dung powder making machine. By equipping yourself with powder making machine, you ought to obtain fine cow dung manure powder. A vertical crusher and a semi-wet material crushing machine are an outstanding option to pulverizing animal manures.

- Small-scale compost turner. A compost turning machine is a fundamental cow dung processing equipment. With the aid of a turning machine, you’ll have much less time for composting. Simultaneously, the labor force will probably be significantly reduced.

Since fresh cow dung contains high moisture, you should dry it first before composting. The cow drying machine can help you get both solid and liquid cow dung manure. It utilizes screw press force to separate the liquid from the available materials. While you collect the solid, the liquid must be discharged using the pump such you could fertilize them into your plants directly.

Just How Do Cow Dung Fertilizer Machines Work with Making Cow Dung to Fertilizer Granules?

When making cow dung fertilizer granules, it’s an absolute necessity to covert the fertilizer powders into fine fertilizer pellets. Aside from the fertilizer powder making machine, you additionally need a fertilizer pellet equipment, drier, cooler, coating machine, and screening equipment. Just how do these appliances make powder into fertilizer pellets?

- Cow dung granulating. A granulator is mostly used for converting powders into pellets. Afterward, it is possible to feed them in to the pellet making machine.

- Drying and cooling. Ever since the granulator makes pellets in extremely high temperatures and implements wet granulation techniques, the finished granules are humid and heated. The drying machine, as well as the cooling machine, will be more convenient in using to create fertilizer pellets.

- Pellets screening. Separate unqualified pellets from the specific products by using rotating screening equipment.

- Quality products coating. By coating the fertilizer granular, it raises the pellets’ physical properties.

Wednesday, 20 May 2020

Chicken Litter Composting Process

Guides to Make Compost From Chicken Litter

Have you been a farmer? Have you realized the advantages of rearing domestic animals? They might include chicken among lots of others. How will you make do of your animal waste? Are you presently familiar with the entire process of composting it? It should be found in the growing of crops since it will make them become healthy plants. In such a case manure is multi-purpose. Imagine having both domestic animals and plants-the benefits will probably be overwhelming! You can even decide to sell it off in return for money. The points that follow show the whole process of making chicken compost manure utilizing a compost windrow turner.

Add Mixtures to the Chicken Dung.

Visit the place where your chicken shelter then you definitely collect the manure. Because it will have dried, you should adjust the degree of moisture to 50% to 60%. Which is the best option level. From that point you will need to seek out C-rich organic waste. This consists of straw powder, sawdust, wood shavings alongside many others. You should mix the C-rich organic waste with all the manure until they already have blended in completely. Chicken manure when combined with straw power the C/N ratio is adjusted to (25:1). In the preparation raw materials are certainly not the only factors considered. You will need a shelter to get the compost pile so that it will never be influenced by bad climate conditions. Detailed info on chicken manure composting, and machines used before chicken manure composting, you can go to https://compostturnermachine.com/compost-material-pretreatment-equipment/

Pile Up the Chicken Manure.

The dimensions should be proper. Once you have collected the chicken manure you will need to stack it in fermentation grooves. However, piling it in up in long rows is very easy. You should consider the place that you simply set aside for this work. Make sure you place in mind the actual size of the compost pile-it matters! Its length depends on the duration of the place you will put aside for composting. The composting windrows turner includes a width of 2 Meters to 3 Meters and a height of .6 Meters to 1.8 Meters. The fermentation groove along with the turner work together to blend the compost pile often. The prior is commonly used to preserve heat and it also consists of three walls using a flexible volume-it is so that you can decide. The groove also uses less space. In this step, we recommend you a fermenting equipment to compost the piled chikcen manure.

Use a Compost Turner Machine Turn The Pile Regularly.

This can be necessary for adjusting the fermentation conditions. A compost pile starts the fermentation process immediately after it can be made since the temperature increases quickly. Once you keep in mind that the temperature has reached 60-70 degrees, you will end up required to turn it. Through the first stage the organic materials are much hence one must turn the compost pile twice or thrice each day. Following the organic materials lessen the turning also reduces to once by two days. In case the raw materials become black and loose along with the temperature becomes constant, it will imply that the fermentation process is going to be done. You do not have to make use of it instantly. You can stack the pile for a few days before you use it. For different types of compost turner machines to make compsots from chicken manure you can go to CTM. to choose your best avaiable machines right there.

These points are already well explained to aid anybody who must make their own chicken compost manure. Stick to the process for the good outcome.

NPK Grnuales Fertilizer Production

The Way To Produce NPK Granules Using NPK Granulation Machines?

NPK fertilizer granules are produced using NPK granulation machines. When it comes to buying NPK fertilizer granulation equipment, it's crucial that you know that you have two different methods of granulating fertilizer: wet and dry. The dry method utilizes extrusion force to press dry powder into pellets. Meanwhile, when using wet drum pelletizers, liquids must be added to the raw materials to offer an adhesive force for granulating. A dry granulation pelletizer is probably the most essential pieces of equipment within an NPK compound fertilizer production line.

Double Roller Press Machine

This kind of machine produces organic fertilizer pellets using extrusion force and will not require any drying processes. The double roller press pellet machine can function at room temperature and could be used to manufacture fertilizer granules in a variety of shapes and sizes. During extrusion granulation, every one of the raw materials are vigorously aggregated under high pressure. The resulting powder will then be squeezed between rollers to produce granules. Since no drying or cooling of fertilizer granules is essential, double roller extrusion granulators are ideal for small to mid-sized organic fertilizer manufacturing plants who may have limited funds for investment in equipment.

Wet Granulation Technology

Wet granulation brings about fertilizer that has a higher moisture content, and so the end product requires drying, cooling and solidifying processes. The four forms of machines which can be used for wet granulation include rotary drum granulator, spray granulation machine, tower spray granulation machine, and disc pan granulation machine. Furthermore, the liquid added through the wet granulation process must be non-toxic and volatilizable. Common additives used are isopropanol and ethyl alcohol. The liquid has to include binders otherwise the very last product will separate during the drying process.

Disc Pan Granulation

The benefits of a disc pan granulator are that it is a lot less than a rotary drum granulator and it has a variety of applications. The disk is made out of strong iron material, rendering it durable and stable. The within the pan is coated within an anti-corrosion plastic glass lining, that is very easy to maintain. During operation, the device produces little noise and is recognized for its reliability. Disc pan granulators are utilized in compound fertilizer production lines that manufacture 50 plus,000 plenty of fertilizer pellets each year.

Finishing Processes

After granulation, you will find additional processes required to complete NPK fertilizer production. If a wet granulating machine was adopted to make the pellets, drying and cooling processes are needed. You can buy drying machines specifically designed for drying and cooling NPK fertilizer granules.

Another stage will be the screening process. In that process, unqualified pellets are removed and sent back for the crushing area of the production line. You could buy different screeners according to your sieving specifications.

The coating process follows the screening process and is also employed to give fertilizer granules a smoother finish in addition to improving their physical characteristics. The packing process is definitely the final stage of production. To boost production efficiency, most companies put money into automatic weighing and bagging machines.

NPK fertilizer granules are produced using NPK granulation machines. When it comes to buying NPK fertilizer granulation equipment, it's crucial that you know that you have two different methods of granulating fertilizer: wet and dry. The dry method utilizes extrusion force to press dry powder into pellets. Meanwhile, when using wet drum pelletizers, liquids must be added to the raw materials to offer an adhesive force for granulating. A dry granulation pelletizer is probably the most essential pieces of equipment within an NPK compound fertilizer production line.

Double Roller Press Machine

This kind of machine produces organic fertilizer pellets using extrusion force and will not require any drying processes. The double roller press pellet machine can function at room temperature and could be used to manufacture fertilizer granules in a variety of shapes and sizes. During extrusion granulation, every one of the raw materials are vigorously aggregated under high pressure. The resulting powder will then be squeezed between rollers to produce granules. Since no drying or cooling of fertilizer granules is essential, double roller extrusion granulators are ideal for small to mid-sized organic fertilizer manufacturing plants who may have limited funds for investment in equipment.

Wet Granulation Technology

Wet granulation brings about fertilizer that has a higher moisture content, and so the end product requires drying, cooling and solidifying processes. The four forms of machines which can be used for wet granulation include rotary drum granulator, spray granulation machine, tower spray granulation machine, and disc pan granulation machine. Furthermore, the liquid added through the wet granulation process must be non-toxic and volatilizable. Common additives used are isopropanol and ethyl alcohol. The liquid has to include binders otherwise the very last product will separate during the drying process.

Disc Pan Granulation

The benefits of a disc pan granulator are that it is a lot less than a rotary drum granulator and it has a variety of applications. The disk is made out of strong iron material, rendering it durable and stable. The within the pan is coated within an anti-corrosion plastic glass lining, that is very easy to maintain. During operation, the device produces little noise and is recognized for its reliability. Disc pan granulators are utilized in compound fertilizer production lines that manufacture 50 plus,000 plenty of fertilizer pellets each year.

Finishing Processes

After granulation, you will find additional processes required to complete NPK fertilizer production. If a wet granulating machine was adopted to make the pellets, drying and cooling processes are needed. You can buy drying machines specifically designed for drying and cooling NPK fertilizer granules.

Another stage will be the screening process. In that process, unqualified pellets are removed and sent back for the crushing area of the production line. You could buy different screeners according to your sieving specifications.

The coating process follows the screening process and is also employed to give fertilizer granules a smoother finish in addition to improving their physical characteristics. The packing process is definitely the final stage of production. To boost production efficiency, most companies put money into automatic weighing and bagging machines.

Monday, 18 May 2020

How to compost poultry litter?

Exactly what is the Best Equipment to Pulverize Composted Poultry Litter?

Poultry manure contains a variety of nutrient elements which are not directly available for crops or plants. You should make it into organic matter in order that the nutrients become absorbable. As well as for that, composting is essential. Poultry litter composting involves microorganisms digesting the manure and producing humic substances. But composting poultry litter is not just like composting horse or cow manure. You require a pulverizing machine to accelerate the composting process.

How pulverizing equipment works

A poultry litter pulverizing machine can process manure with moisture content between 25 and 55%. Unlike horse manure where you must setup a compost pile, a pulverizing machine follows a mechanical process to deliver topsoil fertilizers. It crushes the litter thoroughly so that there is absolutely no trouble aerating it when the entire content goes inside the equipment.

The pulverizer crushes the poultry litter material into a fine powder. It then goes through the fertiliser production line, gets sprayed with water, and after that into the composting chamber. The pre-heated chamber quickly decomposes the manure within a few hours and definitely makes the fertilizer ready.

Types of poultry litter pulverizing equipment

There are actually three machines appropriate for pulverizing poultry manure. These machines include a fermentation groove with a couple of walls offering heat preservation for quick decomposition.

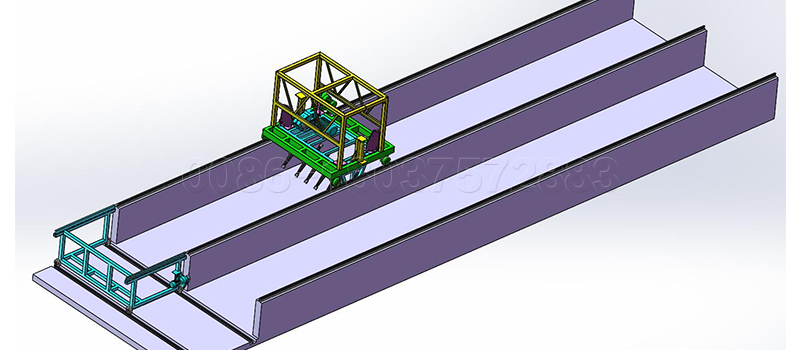

1. Groove type compost turner

This type of machine uses a control cabinet to automatically finish turning compost. Remember, the manure will be in powdered form. Therefore, you don’t need to crush it separately or manually. The device also includes a stirring apparatus by using a hydraulic drive that increases the efficiency of composting. The advanced versions of this machine have double-groove compost turners. They are perfect for large poultry litter composting.

2. Wheel type compost turner

Stirring the manure evenly is crucial for almost any litter. Whether it be horse manure or poultry litter, stirring provides much-needed aeration for the compost so the essential bacteria could work quickly. Inside a wheel type compost turner, the stirring wheel turns the manure thoroughly. With 25 to 55% moisture present in the poultry litter, twisting and turning the manure shortens the composting period. Moreover, with temperature adjusting systems available, you may raise the heat slightly to create the composting chamber humid. This can allow the bacteria to decompose the litter quickly.

3. Chain plate type compost turner

This type of machine is fantastic for deep-groove operation. In order to produce fertilizers in massive quantities, you should use a chain plate type compost turner. But unlike other machines, this once doesn’t include a compost chamber. It has a designated area where you have to dump the poultry litter. The machine will give you appropriate oxygen and temperature to create full fermentation and provide high-quality organic fertilizer in close to almost no time.

With three machines easily accessible to pulverize poultry litter, you shouldn’t waste the daily manure delivered through your cattle. Make manure as the temperature is appropriate, then sell these to local farmers so they don’t use artificial fertilizers.

Poultry manure contains a variety of nutrient elements which are not directly available for crops or plants. You should make it into organic matter in order that the nutrients become absorbable. As well as for that, composting is essential. Poultry litter composting involves microorganisms digesting the manure and producing humic substances. But composting poultry litter is not just like composting horse or cow manure. You require a pulverizing machine to accelerate the composting process.

How pulverizing equipment works

A poultry litter pulverizing machine can process manure with moisture content between 25 and 55%. Unlike horse manure where you must setup a compost pile, a pulverizing machine follows a mechanical process to deliver topsoil fertilizers. It crushes the litter thoroughly so that there is absolutely no trouble aerating it when the entire content goes inside the equipment.

The pulverizer crushes the poultry litter material into a fine powder. It then goes through the fertiliser production line, gets sprayed with water, and after that into the composting chamber. The pre-heated chamber quickly decomposes the manure within a few hours and definitely makes the fertilizer ready.

Types of poultry litter pulverizing equipment

There are actually three machines appropriate for pulverizing poultry manure. These machines include a fermentation groove with a couple of walls offering heat preservation for quick decomposition.

1. Groove type compost turner

This type of machine uses a control cabinet to automatically finish turning compost. Remember, the manure will be in powdered form. Therefore, you don’t need to crush it separately or manually. The device also includes a stirring apparatus by using a hydraulic drive that increases the efficiency of composting. The advanced versions of this machine have double-groove compost turners. They are perfect for large poultry litter composting.

2. Wheel type compost turner

Stirring the manure evenly is crucial for almost any litter. Whether it be horse manure or poultry litter, stirring provides much-needed aeration for the compost so the essential bacteria could work quickly. Inside a wheel type compost turner, the stirring wheel turns the manure thoroughly. With 25 to 55% moisture present in the poultry litter, twisting and turning the manure shortens the composting period. Moreover, with temperature adjusting systems available, you may raise the heat slightly to create the composting chamber humid. This can allow the bacteria to decompose the litter quickly.

3. Chain plate type compost turner

This type of machine is fantastic for deep-groove operation. In order to produce fertilizers in massive quantities, you should use a chain plate type compost turner. But unlike other machines, this once doesn’t include a compost chamber. It has a designated area where you have to dump the poultry litter. The machine will give you appropriate oxygen and temperature to create full fermentation and provide high-quality organic fertilizer in close to almost no time.

With three machines easily accessible to pulverize poultry litter, you shouldn’t waste the daily manure delivered through your cattle. Make manure as the temperature is appropriate, then sell these to local farmers so they don’t use artificial fertilizers.

Tips for compost turner selection

How to find a cost effective compost turner machine to produce quality fertilizer?

Turning machines are widely found in organic composting. This machine enables you to efficiently and effectively produce volumes of compost both over a large-scale and small-scale. It mechanizes the procedure of turning and mixing raw materials to create high-quality fertilizer. However, if you are looking to invest in this equipment to control your manure composting operation, then there are many of things that you need to consider. You may have to bear in mind that we now have differing types and sizes of compost turner machines, and you also can't go on a one-size-fits-all approach when selecting one for your business. You should know the best type and size which fits your unique requirements. To experience this, here are many factors you need to consider:

1. Compost Size and Space

Dependant upon the quantity of compost that you need and also the available space, you have got to pick a turner machine that fits these requirements and specifications. If you are a big farm or factory, then you definitely will definitely need to invest in a sizable compost turner machines as the compost production requirements will be higher. However, when you are a compact farm or have limited space, then this small-sized compost turner machine would be the best option.

2. Climate

In the event you operate in areas that constantly experience cold temperatures, then you will have to build large windrows. Simply because the larger size will help to maintain the pile insulated, thus it will continue to be active and fermentation continues uninterrupted during the entire winter weather. Hence, if your compost production requirements aren't relatively small and you function in colder climates a large turner machine is the perfect option. More info on the organic waste composting tech, go to https://compostturnermachine.com/compost-technology/

3. Sort of Compost Raw Materials

Based on the form of raw materials that you simply decide to use, you will need to identify the best type compost turner machine to choose. For organic materials that feature viscosity including sludge from your sewage treatment plant, you must choose a compost turner with soft-pile turning to help in faster removal of water and quicken fermentation. For materials who have small viscosity and get good fiber, then you may need a compost turner with strong smash and agitation function to make the types of materials lose and uniform. Detailed info on organic fertilizer materials, welcome to https://compostturnermachine.com/compost-materials/

4. Maintenance Requirements

Considering a compost turner carries out rugged work, it can be subject to regular damage. Components tend to be in need of repairs, replacements, and care. Hence, it is actually useful to compare different types and consider individuals with impressive maintenance and repair histories.

5. Transport

If you'll need to constantly should move the equipment to several sites or remote locations, then the simplicity of transporting the equipment should be thought about. Go for a compost turner machine which has portability features including one which has wheels and/or retractable components.

6. Renting or Purchase

For small farms, it might be more practical to rent while for large farms and factories, it could be more economically practical to purchase one. Welcome to CTM select your best compost turner machines for your compost production plant.

Turning machines are widely found in organic composting. This machine enables you to efficiently and effectively produce volumes of compost both over a large-scale and small-scale. It mechanizes the procedure of turning and mixing raw materials to create high-quality fertilizer. However, if you are looking to invest in this equipment to control your manure composting operation, then there are many of things that you need to consider. You may have to bear in mind that we now have differing types and sizes of compost turner machines, and you also can't go on a one-size-fits-all approach when selecting one for your business. You should know the best type and size which fits your unique requirements. To experience this, here are many factors you need to consider:

1. Compost Size and Space

Dependant upon the quantity of compost that you need and also the available space, you have got to pick a turner machine that fits these requirements and specifications. If you are a big farm or factory, then you definitely will definitely need to invest in a sizable compost turner machines as the compost production requirements will be higher. However, when you are a compact farm or have limited space, then this small-sized compost turner machine would be the best option.

2. Climate

In the event you operate in areas that constantly experience cold temperatures, then you will have to build large windrows. Simply because the larger size will help to maintain the pile insulated, thus it will continue to be active and fermentation continues uninterrupted during the entire winter weather. Hence, if your compost production requirements aren't relatively small and you function in colder climates a large turner machine is the perfect option. More info on the organic waste composting tech, go to https://compostturnermachine.com/compost-technology/

3. Sort of Compost Raw Materials

Based on the form of raw materials that you simply decide to use, you will need to identify the best type compost turner machine to choose. For organic materials that feature viscosity including sludge from your sewage treatment plant, you must choose a compost turner with soft-pile turning to help in faster removal of water and quicken fermentation. For materials who have small viscosity and get good fiber, then you may need a compost turner with strong smash and agitation function to make the types of materials lose and uniform. Detailed info on organic fertilizer materials, welcome to https://compostturnermachine.com/compost-materials/

4. Maintenance Requirements

Considering a compost turner carries out rugged work, it can be subject to regular damage. Components tend to be in need of repairs, replacements, and care. Hence, it is actually useful to compare different types and consider individuals with impressive maintenance and repair histories.

5. Transport

If you'll need to constantly should move the equipment to several sites or remote locations, then the simplicity of transporting the equipment should be thought about. Go for a compost turner machine which has portability features including one which has wheels and/or retractable components.

6. Renting or Purchase

For small farms, it might be more practical to rent while for large farms and factories, it could be more economically practical to purchase one. Welcome to CTM select your best compost turner machines for your compost production plant.

Friday, 15 May 2020

How to make cow dung compost fertilizer

With the increase in cattle rearing, the matter of manure pollution has turned into a serious problem for a few. It brings about foul smell if not well maintained and helps to make the environment look messy. In many areas, you may even learn that the level of environmental pollution by cow dung has exceeded the total amount of industrial pollution. This only means something: that men and women should find out how you can convert cow dung into organic fertilizers. It is a smart and economical move because farmers who keep cows and grow plants won’t should buy artificial fertilizers to utilize with their gardens. It is now time to think about the best way to convert the cow dung into organic fertilizer to further improve efficiency and then make things easier for you. There are many cow manure management techniques. You should enable the cow dung to compost since this helps to make the whole process a lot easier. During composting, the microorganisms are the type liable for deteriorating the organic matter into compost. You merely need the raw materials and time and energy to process the compost. Below are ways to convert cow dung into organic fertilizer.

How Can You Prepare Fertilizer From Cow Dung?

After accumulating cow dung, locate a fertilizer compost turner. A fertilizer compost burner aids the microorganism agent to decompose the cow dung in a short period. Without composting, you can not directly utilize the cow dung for plants. You can not miss this task since it is crucial to make organic fertilizers from cow dung. During this period of fermenting, you ought to control the temperature to guarantee effective fermentation occurs. Also, note that it is okay for your cow dung to contain some quantity of moisture, and hence, this shouldn’t be considered a problem. When you are making fertilizer with a small-scale, our recommendation is that you employ the small window turner for this function.

Fertilizer Crusher.

After fermentation and composting, another process involves obtaining a fertilizer crusher. You want the fertilizer crusher to crush the cow dung manure in to a very fine powder. After crushing, put that powder into a fertilizer mixer. The fertilizer mixer helps to ensure that the powder cow dung is mixed evenly. Proceed through a fertilizer pelletizer. The purpose of using this would be to grind the powdery cow manure into granules. Be aware that after granulating, the granules will have high moisture content. It really is, therefore, vital that you remove any moisture from the cow dung pellets. It doesn’t need to be complicated. You might even decide to dry it by natural air, which will still do just fine. There are several machines you could also buy that will help you to lower the moisture content of your pelleted cow dung fertilizers. If you wish excellent cow dung granules, you need to screen the cow manure granules. Pack the best pellets and return the unqualified pellets to be crashed and re-granulated.

Converting cow dung into organic fertilizers shouldn’t be hard. You only have to understand the procedure and know which equipment you have to have the process easier. It will be tough for the first time, but when you will get the hang from it, it gets easier.

How Can You Prepare Fertilizer From Cow Dung?

After accumulating cow dung, locate a fertilizer compost turner. A fertilizer compost burner aids the microorganism agent to decompose the cow dung in a short period. Without composting, you can not directly utilize the cow dung for plants. You can not miss this task since it is crucial to make organic fertilizers from cow dung. During this period of fermenting, you ought to control the temperature to guarantee effective fermentation occurs. Also, note that it is okay for your cow dung to contain some quantity of moisture, and hence, this shouldn’t be considered a problem. When you are making fertilizer with a small-scale, our recommendation is that you employ the small window turner for this function.

Fertilizer Crusher.

After fermentation and composting, another process involves obtaining a fertilizer crusher. You want the fertilizer crusher to crush the cow dung manure in to a very fine powder. After crushing, put that powder into a fertilizer mixer. The fertilizer mixer helps to ensure that the powder cow dung is mixed evenly. Proceed through a fertilizer pelletizer. The purpose of using this would be to grind the powdery cow manure into granules. Be aware that after granulating, the granules will have high moisture content. It really is, therefore, vital that you remove any moisture from the cow dung pellets. It doesn’t need to be complicated. You might even decide to dry it by natural air, which will still do just fine. There are several machines you could also buy that will help you to lower the moisture content of your pelleted cow dung fertilizers. If you wish excellent cow dung granules, you need to screen the cow manure granules. Pack the best pellets and return the unqualified pellets to be crashed and re-granulated.

Converting cow dung into organic fertilizers shouldn’t be hard. You only have to understand the procedure and know which equipment you have to have the process easier. It will be tough for the first time, but when you will get the hang from it, it gets easier.

Thursday, 14 May 2020

Pellet Composting Tech

Many reasons exist to select a rotary granulator and one of those involves the actual design elements. You are likely to be adding an original tool to the machinery when you are down this path.

A lot of businesses have to optimize their granulating operations, which implies they need to start out with a rotary granulator.

Let's check out exactly what the rotary granulator is centered on and why it is one of the most essential investments a facility can certainly make while they try to piece things together.

It starts off with the stainless-steel design as that will be on the top of your thoughts. In case the goal is to make certain the granulating is going on as you would like it to then it is time to think about getting a new rotary granulator. The delicate nature on this machine is seen due to its outer layer. It really is a rugged setup that is going to handle your needs without delay.

Setup the rotary granulator and let it run within the background while handling the fertilization process. The development line will be 10 times faster by using a rotary granulator.

The lining is among the main aspects of the rotary granulator and why is it impressive. It is one of those details which are unnoticed up until the rotary granulator begins to move and browse through the organic waste. The granulation process goes ahead smoothly given that the lining holds up. As a result, the rubber plate lining is made to stand up to a huge amount of pressure at different temperatures. This allows the organic waste to carry on to process through without missing a beat. Here is the real power of a great rotary granulator.

It's about working with different temperatures in relation to the complete process. This is certainly something lots of operations don't center on yet it is a big part of your granulating process. With a high-grade rotary granulator, you get to take advantage of this immediately. It could be a game-changer for any individual which is serious about granulating the correct way and wishes to see serious results. The high quality will likely be apparent and that is certainly why this is among one of those intriguing investments businesses look to make as soon as they can.

The rotary granulator is a fantastic option mainly because it works similar to a charm. It's everything about the overall design and ensuring there's value in what you are actually getting once it is placed. The high quality sticks out for people interested in the things they use for granulating. The fragile nature from the process and the way organic waste has to be managed means it's always going ahead to the rotary granulator. This is one of the more robust strategies to have on your side after it is a chance to figure things out and optimize your granulating.

A lot of businesses have to optimize their granulating operations, which implies they need to start out with a rotary granulator.

Let's check out exactly what the rotary granulator is centered on and why it is one of the most essential investments a facility can certainly make while they try to piece things together.

Stainless Design

It starts off with the stainless-steel design as that will be on the top of your thoughts. In case the goal is to make certain the granulating is going on as you would like it to then it is time to think about getting a new rotary granulator. The delicate nature on this machine is seen due to its outer layer. It really is a rugged setup that is going to handle your needs without delay.

Setup the rotary granulator and let it run within the background while handling the fertilization process. The development line will be 10 times faster by using a rotary granulator.

Rubber Plate Lining

The lining is among the main aspects of the rotary granulator and why is it impressive. It is one of those details which are unnoticed up until the rotary granulator begins to move and browse through the organic waste. The granulation process goes ahead smoothly given that the lining holds up. As a result, the rubber plate lining is made to stand up to a huge amount of pressure at different temperatures. This allows the organic waste to carry on to process through without missing a beat. Here is the real power of a great rotary granulator.

Cooling and Heating Mechanisms

It's about working with different temperatures in relation to the complete process. This is certainly something lots of operations don't center on yet it is a big part of your granulating process. With a high-grade rotary granulator, you get to take advantage of this immediately. It could be a game-changer for any individual which is serious about granulating the correct way and wishes to see serious results. The high quality will likely be apparent and that is certainly why this is among one of those intriguing investments businesses look to make as soon as they can.

The rotary granulator is a fantastic option mainly because it works similar to a charm. It's everything about the overall design and ensuring there's value in what you are actually getting once it is placed. The high quality sticks out for people interested in the things they use for granulating. The fragile nature from the process and the way organic waste has to be managed means it's always going ahead to the rotary granulator. This is one of the more robust strategies to have on your side after it is a chance to figure things out and optimize your granulating.

Wednesday, 13 May 2020

Make Compost at Small Scale

Beginning an organic fertilizer business are often very lucrative. There exists a huge interest in organic fertilizer and you will allow it to be easily without building a huge investment. When you are new to the organic fertilizer business you desire to ensure that you invest in a small-scale organic production line. This allows you to enter into the organization without building a huge investment.

The production line takes many different kinds of organic waste and turns them into fertilizer. The production line will process the waste and manure and transform it into safe organic fertilizer that one could sell. The appliance is simple to operate and is particularly reliable. You may trust it to work hard for you personally and you have a big return on your own investment when. The appliance was created to produce manure efficiently and effectively. The device is user friendly and features a compact design which makes it simple to fit anywhere.

The appliance has a crusher that crushes the manure before it can be loaded into the belt conveyor. The conveyor moves the manure towards the stove where it is processed into fertilizer. It then explores a dryer to be dried. As soon as the fertilizer is dried it is transported in the conveyor belt on the hopper where it goes on the packing area. The device does everything. It generates the fertilizer effortlessly and you can easily package it up and then sell it once you are done with it.

You can use different styles of manure with all the plant. It can be used with cow, chicken, and horse manure. The plant ferments the manure for as long as it will require to change into fertilizer. It takes approximately monthly for your manure to ferment. If you wish it to ferment faster you need a compost turner. You can add the turner to the order so you produce the fertilizer faster.

Prior to using the equipment you want to crush the manure it is therefore good to go in the machine. The type of material must be crushed before they go into the machine and that means you will probably want to purchase a crusher also. Making organic fertilizer can be quite profitable and it allows you to earn more income. The manure is cheap and also you won't need to spend a ton of money buying it.

If you already have a poultry farm it is possible to invest in one of these simple plants in an effort to earn more income faster. The equipment is affordable and it gives you more of what you need. If you are willing to make more cash and take your business to another level it will likely be important to buy one of these brilliant plants.

Be sure that the size of small-scale organic fertilizer plant is right for your requirements and be sure to have anything else that you should opt for the equipment. The manufacturer can assist you select the right machine for your personal business.

The production line takes many different kinds of organic waste and turns them into fertilizer. The production line will process the waste and manure and transform it into safe organic fertilizer that one could sell. The appliance is simple to operate and is particularly reliable. You may trust it to work hard for you personally and you have a big return on your own investment when. The appliance was created to produce manure efficiently and effectively. The device is user friendly and features a compact design which makes it simple to fit anywhere.

The appliance has a crusher that crushes the manure before it can be loaded into the belt conveyor. The conveyor moves the manure towards the stove where it is processed into fertilizer. It then explores a dryer to be dried. As soon as the fertilizer is dried it is transported in the conveyor belt on the hopper where it goes on the packing area. The device does everything. It generates the fertilizer effortlessly and you can easily package it up and then sell it once you are done with it.

You can use different styles of manure with all the plant. It can be used with cow, chicken, and horse manure. The plant ferments the manure for as long as it will require to change into fertilizer. It takes approximately monthly for your manure to ferment. If you wish it to ferment faster you need a compost turner. You can add the turner to the order so you produce the fertilizer faster.

Prior to using the equipment you want to crush the manure it is therefore good to go in the machine. The type of material must be crushed before they go into the machine and that means you will probably want to purchase a crusher also. Making organic fertilizer can be quite profitable and it allows you to earn more income. The manure is cheap and also you won't need to spend a ton of money buying it.

If you already have a poultry farm it is possible to invest in one of these simple plants in an effort to earn more income faster. The equipment is affordable and it gives you more of what you need. If you are willing to make more cash and take your business to another level it will likely be important to buy one of these brilliant plants.

Be sure that the size of small-scale organic fertilizer plant is right for your requirements and be sure to have anything else that you should opt for the equipment. The manufacturer can assist you select the right machine for your personal business.

Monday, 11 May 2020

Recycling Animal Manure

Where Is It Possible To Work With A Fertilizer Dryer For Recycling Animal Manure?

Let's assume you are handling animal manure and would like to ensure the procedure is as straightforward as is possible. This isn't likely to mean you add up a production line and hope to find the best.

Instead, you will have to take one step back and select a fertilizer dryer. It is a must you should do things the correct way or you will be stuck in the tough spot that isn't easy to get out of.

This is a detailed look at where and when you can begin by using a fertilizer dryer for recycling animal manure.

Preparation for Long-Term Storage

Most animal manure is going to be stored for very long periods because it isn't gonna be used right away. This means you ought to prepare properly and make sure things are considered in your end. Otherwise, you are going to have low-grade animal manure that isn't going to be suitable for storing.

Most businesses may wish to set up your pet manure after it is through the production line, which suggests they will store it for too long periods.

If that is the situation, the fertilizer dryer should be excited to remove water content within the animal manure. This really is a must.

Consistent Processing

One of the greatest hurdles that come with an activity similar to this may be the processing. You are able to browse through the right organic materials and even make use of the best machinery however it is this step that will matter a whole lot. You have to make sure the fertilizer dryer is used right after the animal manure has become prepped.

This will cause consistent manure that is certainly in accordance with what you really are trying to get from the process. As time passes, this consistency is going to yield value.

Increase in Quality

The aim is to experience a fertilizer dryer good to go as soon as the production line has been doing its work. Generally, you will get the chance to believe things are okay and therefore means the manure could be processed "as they are" without having done anything. However, it is a major mistake for the reason that quality will depreciate immediately. You will end up having an asset that may be okay for a few days however begins to fall apart as a result of increased water content.

After it is time to set up a fertilizer dryer, it is very important comprehend the benefits that come with the equipment and why it is handy during the process. You don't want a production line being create that doesn't make up this as that is a major hurdle continuing to move forward. Your goal must be to keep things as elementary as possible and this means receiving the fertilizer dryer operational as soon as possible.

Once you accomplish this, the animal manure will be recycled correctly and definately will cause better results.

Let's assume you are handling animal manure and would like to ensure the procedure is as straightforward as is possible. This isn't likely to mean you add up a production line and hope to find the best.

Instead, you will have to take one step back and select a fertilizer dryer. It is a must you should do things the correct way or you will be stuck in the tough spot that isn't easy to get out of.

This is a detailed look at where and when you can begin by using a fertilizer dryer for recycling animal manure.

Preparation for Long-Term Storage

Most animal manure is going to be stored for very long periods because it isn't gonna be used right away. This means you ought to prepare properly and make sure things are considered in your end. Otherwise, you are going to have low-grade animal manure that isn't going to be suitable for storing.

Most businesses may wish to set up your pet manure after it is through the production line, which suggests they will store it for too long periods.

If that is the situation, the fertilizer dryer should be excited to remove water content within the animal manure. This really is a must.

Consistent Processing

One of the greatest hurdles that come with an activity similar to this may be the processing. You are able to browse through the right organic materials and even make use of the best machinery however it is this step that will matter a whole lot. You have to make sure the fertilizer dryer is used right after the animal manure has become prepped.

This will cause consistent manure that is certainly in accordance with what you really are trying to get from the process. As time passes, this consistency is going to yield value.

Increase in Quality

The aim is to experience a fertilizer dryer good to go as soon as the production line has been doing its work. Generally, you will get the chance to believe things are okay and therefore means the manure could be processed "as they are" without having done anything. However, it is a major mistake for the reason that quality will depreciate immediately. You will end up having an asset that may be okay for a few days however begins to fall apart as a result of increased water content.

After it is time to set up a fertilizer dryer, it is very important comprehend the benefits that come with the equipment and why it is handy during the process. You don't want a production line being create that doesn't make up this as that is a major hurdle continuing to move forward. Your goal must be to keep things as elementary as possible and this means receiving the fertilizer dryer operational as soon as possible.

Once you accomplish this, the animal manure will be recycled correctly and definately will cause better results.

Disc Compost Pelletizer Working Principle

How does a disc granulator work for making your powdery fertilizers into granules?

Making your powder fertilizers into granules is essential, whether you want to sell or make use of them all by yourself crops. The whole process of turning powdery materials into granules demands a disc granulator. This machine can manufacture organic fertilizer in line with your unique requirements. Here's a concise description of this process, so that you can understand why and how to choose this sort of equipment for your personal fertilizer production plant.

A disc granulator consists from several devices, all of them with its own role with this process. The driving part accounts for making the shaft turn, thanks to belt pulleys plus a gear wheel. This piece of equipment drives the material into the pelleting disc, which is the most essential portion of the machine, the place where the powder is transformed into granules. The faster this disc rotates, the better the working efficiency of the machine. Nevertheless, there's a speed limitation, so you won't have the capacity to pick just any value you want. One of the more important things to remember is by governing the disc inclination, you'll be able to make high quality pellets. Last but not least, the device contains a scraper, that is installed on top of the pelleting disc. The scraper prevents the material from adhering to the disc wall. It can also help cleansing the disc from time to time, in order to prevent unwanted accumulations of material onto its surface.

This equipment uses wet granulation methods for making powdery fertilizers into pellets. A lot of people would rather include liquid to boost the adhesive force. As a result powders rotate within the disc until they become round granules. This process relies upon centrifugal force to unfold. In the last stage of the production process, these granules exit through the foot of the disc. Many small enterprises prefer this type of granulator, as it is for sale in sizes that fit labs and smaller firms that would like to manufacture their own fertilizer pellets to work with on their plants rather than buying them from third parties. Such situations, there's no need for mass production capacities, so a reduced machine would just do fine.

Of course, the fertilizer granules production line may also feature a packing machine. This piece of equipment is nothing but an automatic scale with a couple of buckets. It is going to pack your fertilizer granules to meet your requirements.

Remember that disc granulators can be found in a wide range of sizes. They might have different rotary speeds, different powers, and therefore different production capacities. Furthermore, it is possible to opt for the size and also the shape of the granules. Many of these machines permit you to manufacture several types of granules. Before purchasing your machines, make certain you completely grasp the way that they work and what are their specific advantages and drawbacks. Always avoid buying such equipment without asking several manufacturers for price estimates. You need to compare multiple offers to get the best decision, so take time to scout the current market in seek for reliable manufacturers of disc granulating machines as well as other such devices.