How to choose the right fertilizer turning machine for composting

Fatty fin fish is mainly used for fertilizer fermentation on the farm. The crushed straw and livestock manure need to be fermented to kill a large number of animal feces bacteria, parasites, etc., so as to transform the compost raw materials and shorten the composting time. It is suitable for the mechanism and technological requirements of microbial fermentation of livestock and poultry manure. It can effectively mix fertilizers with microbial preparations and plant straws to create a good aerobic environment for raw material fermentation.

Under this loose material condition, livestock and poultry manure can be heated for 2 days, deodorized for 3 days, and fertilized for about 15 days, effectively preventing the generation of harmful gases such as hydrogen sulfide and amine gas during fermentation, that is, environmental protection and good Bio-organic fertilizer production.

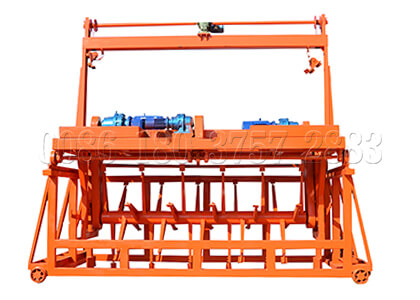

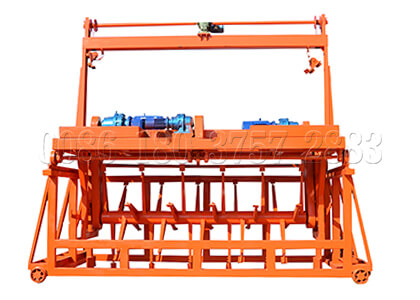

Material pile compost turning machine

The pile turning machine adopts a pile-type ground fermentation process and uses a soft-start steering clutch. The hydraulic push plate does not require manual stacking of raw materials. The use of drum-type hydraulic lifting can greatly save space, time, diesel and manpower, and shorten the fermentation cycle.

It is suitable for small batch production turnover of organic fertilizer, with good economic benefits and low investment.

Simple stacker

It is suitable for aerobic fermentation and can be used in conjunction with solar fermentation chambers, fermentation tanks and mobile machinery. It can be used with mobile machines to realize the function of multiple slots of a machine. The fermentation tank can be discharged continuously or intermittently, with high efficiency, stable operation, firm and durable, and even spreading.

The centralized control of the control cabinet can realize manual or automatic control functions, the electric shovel is durable, the material has a certain number of crushing and mixing functions, and the limit travel switch can play a safety and limit role.

The stacker has high efficiency, stable operation, firmness and durability, and even toss. Widely welcomed by customers, it is the best lathe that our company sells.

How to choose the right fertilizer applicator

Twin-screw compost truck

Feature

. Stirring in raw material conditioning.

. Adjust the temperature of the material stack.

. Improve the permeability of the raw material pile.

. Adjust the water in the raw material pile.

. Realize the special requirements of the composting process.

The screw type compost turning machine is suitable for mass production of organic fertilizer and has economies of scale.

Compost Making Tech, introduces you all the leading compost production technologies, facilities, formulars you want to know

Wednesday, 10 June 2020

Tuesday, 9 June 2020

raw materials of organic fertilizer

Application of organic fertilizer is the key to maintain and improve soil fertility. It is also an important measure to achieve sustainable agricultural development and the recycling of various nutrients. Organic fertilizer plays an important role in balancing crop nutrient supply, improving product quality, and increasing crop yield.

Organic fertilizer raw materials for production

1. Livestock manure

Pig manure, cow manure, horse manure, sheep manure, rabbit manure, poultry manure, silkworm sand, sea bird manure.

Go to SX Livetock Manure Processing for more details.

2. Straw and other plant residues

Straw, straw, corn stover, soybean straw, rape straw, etc. all contain high cellulose and lignin, and are generally used to increase the organic matter of fermentation materials and adjust the C/N ratio. SX CTM introduce detailed steps on plant residue processing into composts, welcome to https://organicfertilizerplants.com/farm-waste-disposal/

3. Cake fertilizer, mushroom residue or furfural residue

Cake fertilizer is the residue of oil extracted from oily seeds, also known as oil cake. It is rich in nutrients, such as bean cake, vegetable cake, peanut cake, tea cake and cypress cake.

Mushroom residue refers to the remaining medium after the edible fungus is harvested, which is mainly composed of the medium and the remaining mycelium.

Furfural residue is the residue discharged from corncob stalks after crushing and adding a certain amount of dilute sulfuric acid under a certain temperature and pressure, after a series of hydrolysis chemical reactions to extract furfural. On mushroom wastes, composting, pls look at how CMSX do, https://compostmachinery.com/mushroom-compost-turner/

4. Sediment in rivers, ponds, ditches and lakes

5. Peat and humic acid

6. Seaweed, etc.

Organic fertilizer raw materials for production

1. Livestock manure

Pig manure, cow manure, horse manure, sheep manure, rabbit manure, poultry manure, silkworm sand, sea bird manure.

Go to SX Livetock Manure Processing for more details.

2. Straw and other plant residues

Straw, straw, corn stover, soybean straw, rape straw, etc. all contain high cellulose and lignin, and are generally used to increase the organic matter of fermentation materials and adjust the C/N ratio. SX CTM introduce detailed steps on plant residue processing into composts, welcome to https://organicfertilizerplants.com/farm-waste-disposal/

Cake fertilizer is the residue of oil extracted from oily seeds, also known as oil cake. It is rich in nutrients, such as bean cake, vegetable cake, peanut cake, tea cake and cypress cake.

Mushroom residue refers to the remaining medium after the edible fungus is harvested, which is mainly composed of the medium and the remaining mycelium.

Furfural residue is the residue discharged from corncob stalks after crushing and adding a certain amount of dilute sulfuric acid under a certain temperature and pressure, after a series of hydrolysis chemical reactions to extract furfural. On mushroom wastes, composting, pls look at how CMSX do, https://compostmachinery.com/mushroom-compost-turner/

5. Peat and humic acid

6. Seaweed, etc.

Monday, 8 June 2020

Chemical Fertilizer VS Organic Fertilizer Granules

Chemical fertilizers, made by chemical or physical methods, contain one or more nutrients needed for the growth of crops. Also called inorganic fertilizer, including nitrogen, phosphorus, potassium, trace elements, compound fertilizer, etc., has the characteristics of strong pertinence and quick results. There are many types of fertilizers, the most common being urea.

Organic fertilizers are formed by various animal and plant residues or metabolites after a certain processing process. It mainly includes agricultural waste, livestock and poultry manure, industrial waste, urban sludge, etc. Organic fertilizer is rich in nutrients and can improve the soil.

Fertilizer pellet machine and organic fertilizer pellet machine

Main fertilizer granulator:

Double roll granulator

The double-roll granulator has the characteristics of compact structure, good stability, good sealing, low noise, easy operation and maintenance, etc. After the new machine is launched, it has won praise from users. It has wide adaptability to raw materials such as chemical fertilizer, feed, chemical industry, especially for rare earth, metallurgy, coal and biological environmental protection. On the other hand, it is also the promotion of environmental engineering.

Disc granulator (disc granulator)

Disc pelletizers are used to make powder into balls, and are widely used in organic fertilizer plants, chemical fertilizer plants, and mining, chemical, and food industries. This machine is used for granulation processing, the appearance of granular products is beautiful, and the size of particle size is large.

Drum granulator

The drum granulator is a fertilizer granulator that can make the material form a specific shape. It is suitable for large-scale production of cold and hot fertilizer granulation production line and high and low concentration compound fertilizer production line.

Main organic fertilizer granulator:

New organic fertilizer granulator

The organic fertilizer granulator is used to granulate various organic substances after fermentation, and is crushed by conventional organic granulation before granulation. The content of organic matter can be as high as 100%, and it is made into pure organic particles, which are spherical.

Ring die granulator

The granulator is used to granulate various organic substances after fermentation, breaking the traditional organic granulation before granulation. There is no need to dry and crush raw materials before granulation. It can directly dispense cylindrical particles and save a lot of energy.

New two-in-one organic fertilizer granulator

The machine can not only granulate a variety of organic matter, especially the crude fiber raw materials that are difficult to granulate with conventional equipment, such as crop straw, wine residue, mushroom residue, medicinal residue, animal feces, etc. It can granulate compound fertilizer. Organic fertilizer and compound fertilizer can be mixed and granulated.

Why organic fertilizer is so popular

Organic fertilizer can improve the damage of the soil, because the organic elements contained in it can restore the vitality of the soil. Excessive use of chemical fertilizers will destroy the soil structure and cause great harm to the soil.

Organic fertilizer improves the plant's resistance to diseases and insect pests, while chemical fertilizer is a single microbial population, prone to diseases and insect pests.

The main equipment of the organic fertilizer production line are: stacker, crusher, screening machine, mixer, granulator, dryer, cooler, screening machine, packaging machine.

Organic fertilizers are formed by various animal and plant residues or metabolites after a certain processing process. It mainly includes agricultural waste, livestock and poultry manure, industrial waste, urban sludge, etc. Organic fertilizer is rich in nutrients and can improve the soil.

Fertilizer pellet machine and organic fertilizer pellet machine

Main fertilizer granulator:

Double roll granulator

The double-roll granulator has the characteristics of compact structure, good stability, good sealing, low noise, easy operation and maintenance, etc. After the new machine is launched, it has won praise from users. It has wide adaptability to raw materials such as chemical fertilizer, feed, chemical industry, especially for rare earth, metallurgy, coal and biological environmental protection. On the other hand, it is also the promotion of environmental engineering.

Disc granulator (disc granulator)

Disc pelletizers are used to make powder into balls, and are widely used in organic fertilizer plants, chemical fertilizer plants, and mining, chemical, and food industries. This machine is used for granulation processing, the appearance of granular products is beautiful, and the size of particle size is large.

Drum granulator

The drum granulator is a fertilizer granulator that can make the material form a specific shape. It is suitable for large-scale production of cold and hot fertilizer granulation production line and high and low concentration compound fertilizer production line.

Main organic fertilizer granulator:

New organic fertilizer granulator

The organic fertilizer granulator is used to granulate various organic substances after fermentation, and is crushed by conventional organic granulation before granulation. The content of organic matter can be as high as 100%, and it is made into pure organic particles, which are spherical.

Ring die granulator

The granulator is used to granulate various organic substances after fermentation, breaking the traditional organic granulation before granulation. There is no need to dry and crush raw materials before granulation. It can directly dispense cylindrical particles and save a lot of energy.

New two-in-one organic fertilizer granulator

The machine can not only granulate a variety of organic matter, especially the crude fiber raw materials that are difficult to granulate with conventional equipment, such as crop straw, wine residue, mushroom residue, medicinal residue, animal feces, etc. It can granulate compound fertilizer. Organic fertilizer and compound fertilizer can be mixed and granulated.

Why organic fertilizer is so popular

Organic fertilizer can improve the damage of the soil, because the organic elements contained in it can restore the vitality of the soil. Excessive use of chemical fertilizers will destroy the soil structure and cause great harm to the soil.

Organic fertilizer improves the plant's resistance to diseases and insect pests, while chemical fertilizer is a single microbial population, prone to diseases and insect pests.

The main equipment of the organic fertilizer production line are: stacker, crusher, screening machine, mixer, granulator, dryer, cooler, screening machine, packaging machine.

Friday, 5 June 2020

Organic Fertilizer Production Procedure

Any smart investor in agriculture knows one thing for certain: Nothing is for waste. With regards to spoiled yield, they can be used green manure, left-overs from harvest bring mulch and in many cases animal waste as manure. They are able to all, however, be also commercialized as fertilizer. Consequently, to make certain success in the industry of creating organic fertilizer within your farm, an operation must be followed for top-quality end product and durability. Listed below are the group of steps to adhere to when you make organic manure:

1. Composting.

This is the turning of organic material into humus through, microbial activity. It is completed to avoid scorching plants by directly depositing the organic material which can release some acidic components. To accomplish this, simply compose a pile of the organic matter on a lawn or even in a trench. For fermentation to occur the correct way, which can be aerobic, keep turning the mixture regularly to make sure oxygen supply. Observe the pile until it is fully fermented: loose, odorless with a reliable temperature of 60℃ or 70 ℃. Ensure the water content is 50-60 percent, some straw or sawdust will have the desired effect. Your previously organic waste now turns into organic fertilizer. More detailed info on fertilizer composting process, welcome to https://compostturnermachine.com/composting-process/

2. Deep processing

This is the technique of making the fertilizer above efficient for commercialization through screening, adding nutrients and packaging, all carried out by a processing plant. It is made of two processes depending on the end product you’d want. They are the Powdery organic fertilizer production and Granular organic fertilizer production. The powdery is actually a short process that goes as follows:

Material Crushing:

The fertilizer is crushed into small refined pieces in order to give a smooth mixed powdery product. This is achieved by using a machine called a crusher. The Vertical crusher, particularly, avoids caking, which is solidifying the powder in a cake-like substance.

Screening:

This really is to eliminate any impurities which may be within your powder, ensuring the high quality of organic fertilizer. It is actually done using a rotary screen machine. For the greatest machine, search for the one that is efficient in screening, requires less maintenance, produces low noise and produces small dust amounts.

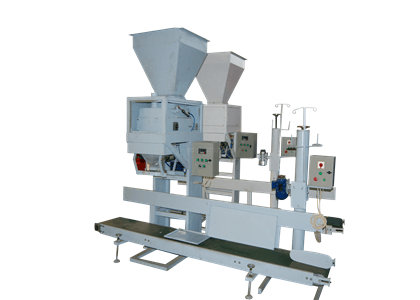

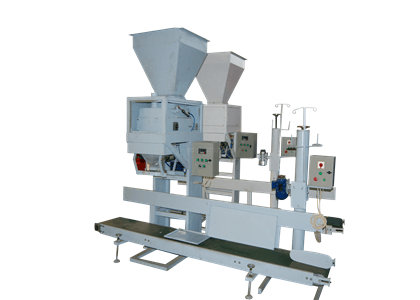

Packaging:

This is the final step for powdered organic fertilizer. It involves enclosing the finished product in bags for distribution, storage, and sale to customers. The most beneficial machines are automatic packing machines.

When it comes to Granular organic fertilizer production, the procedure is a little bit more complex and involves a few more steps and machines, therefore. It is going as follows:

Crushing:

This is certainly necessary to produce powdery organic fertilizer and is equivalent to usually the one before.

Mixing:

Granular processing demands a highly refined homogenous powder. Additional nutrient elements and functional bacterial can also be added to increase the grade of fertilizer. They may be then mixed together thoroughly by using a disc mixer.

Pelletizing:

This step turns the mixed powder into pellets or granules. Pelletizers can be used for this task. Pellets are simpler to store, manage and package when compared with powder so this is the preferred state of your finished product.

Drying and cooling:

It aims at reducing the water content to improve shelf life.

Screening and packaging.

These adhere to the powder process mentioned there before, only, in such a case, the procedure is on pellets.

In conclusion, the process can provide great value for you personally since everyone seems to be diverging from chemical fertilizers to organic ones. This said it really is a worthy investment.

1. Composting.

This is the turning of organic material into humus through, microbial activity. It is completed to avoid scorching plants by directly depositing the organic material which can release some acidic components. To accomplish this, simply compose a pile of the organic matter on a lawn or even in a trench. For fermentation to occur the correct way, which can be aerobic, keep turning the mixture regularly to make sure oxygen supply. Observe the pile until it is fully fermented: loose, odorless with a reliable temperature of 60℃ or 70 ℃. Ensure the water content is 50-60 percent, some straw or sawdust will have the desired effect. Your previously organic waste now turns into organic fertilizer. More detailed info on fertilizer composting process, welcome to https://compostturnermachine.com/composting-process/

2. Deep processing

This is the technique of making the fertilizer above efficient for commercialization through screening, adding nutrients and packaging, all carried out by a processing plant. It is made of two processes depending on the end product you’d want. They are the Powdery organic fertilizer production and Granular organic fertilizer production. The powdery is actually a short process that goes as follows:

Material Crushing:

The fertilizer is crushed into small refined pieces in order to give a smooth mixed powdery product. This is achieved by using a machine called a crusher. The Vertical crusher, particularly, avoids caking, which is solidifying the powder in a cake-like substance.

Screening:

This really is to eliminate any impurities which may be within your powder, ensuring the high quality of organic fertilizer. It is actually done using a rotary screen machine. For the greatest machine, search for the one that is efficient in screening, requires less maintenance, produces low noise and produces small dust amounts.

Packaging:

This is the final step for powdered organic fertilizer. It involves enclosing the finished product in bags for distribution, storage, and sale to customers. The most beneficial machines are automatic packing machines.

When it comes to Granular organic fertilizer production, the procedure is a little bit more complex and involves a few more steps and machines, therefore. It is going as follows:

Crushing:

This is certainly necessary to produce powdery organic fertilizer and is equivalent to usually the one before.

Mixing:

Granular processing demands a highly refined homogenous powder. Additional nutrient elements and functional bacterial can also be added to increase the grade of fertilizer. They may be then mixed together thoroughly by using a disc mixer.

Pelletizing:

This step turns the mixed powder into pellets or granules. Pelletizers can be used for this task. Pellets are simpler to store, manage and package when compared with powder so this is the preferred state of your finished product.

Drying and cooling:

It aims at reducing the water content to improve shelf life.

Screening and packaging.

These adhere to the powder process mentioned there before, only, in such a case, the procedure is on pellets.

In conclusion, the process can provide great value for you personally since everyone seems to be diverging from chemical fertilizers to organic ones. This said it really is a worthy investment.

Thursday, 4 June 2020

Choose Compost Machines Based on Technology

The compost turner machine's primary job is for making organic fertilizer. This procedure happens throughout the fermentation and composting of organic wastes like garbage filters, sludge from industries, mud straw, as well as animal manure, amongst other things. The procedure is inexpensive and in addition ensures zero environmental degradation. The most frequent means of composting is truly the natural way of fermenting by permitting these waste rot away. However, the compost turner machine is very efficient since it adopts these types of technological advancements.

Windrow Composting.

Also referred to as aerated or turned composting. This technology of composting is quite efficient for larger volumes of substances. Almost all of this waste will come from communities hence the extensive collection done by the regional government in a central place. Businesses with good-end food processing activities like restaurants also play a substantial role. This process works by forming organic waste into rows from the name windrows. Later, there exists aeration that can take place at intervals. The ideal windrow height is between four to eight feet, based on the use. Using the size, there exists a guarantee which it will achieve including the flow of oxygen, and enough heat will pass to aid retain the temperatures. Compost Turner taht use windrow composting tech, welcome to https://compostturnermachine.com/compost-windrow-turner/

Vermicomposting

You may always find worms in waste bins, which is their supply of food. However, this feeding helps a whole lot in the creating of compost from your available waste. The waste is split up into high-quality compost through the name castings. Using this technology, worms are actually an excellent business when you quickly purchase them from the market. Therefore, it is very important place this waste in quantities dependant upon the intake of the worms. One pound of worms can eat up to half-pound of organic material. This method takes almost four months to complete. The castings are beneficial since they are available as potting soil. Also, there is certainly another by-product of this technology called worm tea, another type of fertilizer. Here are detailed info and machines related to vermicomposting technology https://manurefertilizermachine.com/industrial-vermicomposting-equipment/

In-Vessel Composting.

This technology is sufficient as it helps with the composting of organic materials by using minimal space as compared to the windrow method. Also, there is a accommodation of an array of materials from animal manure, food scraps, and biosolids, among other elements. The substances enter into a silo or any other equipment equivalent to a drum. This vacuum ensures there are actually stable airflow and temperature. Mixing from the materials then starts for several minutes to boost aeration. The method takes to a couple of weeks just before the compost is prepared. You use various sizes of drums based on the need of use. More info on in-vessel composting, welcome to https://compostmachinery.com/in-vessel-composting/

Onsite Composting.

Onsite composting can be a composting method efficient for places with minimal levels of organic materials. Organizations producing yard trimmings and average food waste can adapt this method for producing their fertilizers. However, animal merchandise is not recommendable for this sort of composting.

Nevertheless, you can find five essential components of these composting technologies which require strict controlling to ensure the processes are successful. Included in this are sizes of particles, temperature, the flow of oxygen, moisture content, and nutrient balance. Adhering these conditions will yield composts of the finest quality.

Windrow Composting.

Also referred to as aerated or turned composting. This technology of composting is quite efficient for larger volumes of substances. Almost all of this waste will come from communities hence the extensive collection done by the regional government in a central place. Businesses with good-end food processing activities like restaurants also play a substantial role. This process works by forming organic waste into rows from the name windrows. Later, there exists aeration that can take place at intervals. The ideal windrow height is between four to eight feet, based on the use. Using the size, there exists a guarantee which it will achieve including the flow of oxygen, and enough heat will pass to aid retain the temperatures. Compost Turner taht use windrow composting tech, welcome to https://compostturnermachine.com/compost-windrow-turner/

Vermicomposting

You may always find worms in waste bins, which is their supply of food. However, this feeding helps a whole lot in the creating of compost from your available waste. The waste is split up into high-quality compost through the name castings. Using this technology, worms are actually an excellent business when you quickly purchase them from the market. Therefore, it is very important place this waste in quantities dependant upon the intake of the worms. One pound of worms can eat up to half-pound of organic material. This method takes almost four months to complete. The castings are beneficial since they are available as potting soil. Also, there is certainly another by-product of this technology called worm tea, another type of fertilizer. Here are detailed info and machines related to vermicomposting technology https://manurefertilizermachine.com/industrial-vermicomposting-equipment/

In-Vessel Composting.

This technology is sufficient as it helps with the composting of organic materials by using minimal space as compared to the windrow method. Also, there is a accommodation of an array of materials from animal manure, food scraps, and biosolids, among other elements. The substances enter into a silo or any other equipment equivalent to a drum. This vacuum ensures there are actually stable airflow and temperature. Mixing from the materials then starts for several minutes to boost aeration. The method takes to a couple of weeks just before the compost is prepared. You use various sizes of drums based on the need of use. More info on in-vessel composting, welcome to https://compostmachinery.com/in-vessel-composting/

Onsite Composting.

Onsite composting can be a composting method efficient for places with minimal levels of organic materials. Organizations producing yard trimmings and average food waste can adapt this method for producing their fertilizers. However, animal merchandise is not recommendable for this sort of composting.

Nevertheless, you can find five essential components of these composting technologies which require strict controlling to ensure the processes are successful. Included in this are sizes of particles, temperature, the flow of oxygen, moisture content, and nutrient balance. Adhering these conditions will yield composts of the finest quality.

Tuesday, 2 June 2020

Guides to Choose Best Compost Making Machine

Compost is absolutely nothing else than recycled organic matter that's very full of nutrients, and therefore an excellent soil conditioner. Even though it costs almost absolutely nothing to make compost, you'll need raw matter along with a special machine. There are many things you may use as raw matter, the most frequent being sawdust pellets, vegetable and fruit scraps, coffee grounds, chicken manure, dead leaves, grass clippings, and also every other type of kitchen and garden waste.

To begin with, you have to determine the amount of matter you want to process every day. Compost machines for commercial and industrial purposes can process from 25 kg per day to 2 tonnes each day. Because this is a significant wide variety, you must narrow it down by determining your actual needs. Always allow some room for growth, if your business develop faster than expected. It wouldn't be too nice to outgrow your equipment in the 1st year of activity. Here are details of compost machines for commercial and industrial purposes https://compostturnermachine.com/commercial-compost-machine/

The productivity rates are another thing to remember when you shop around to find the best machine to make compost. If you want each of the speed you will get, you'd better make an effort to purchase a fully automatic machine. In the event that productivity doesn't matter just as much, you might like to pick a semi-automatic machine instead.

Whatever your decision, ensure that you pick a machine featuring a powerful inbuilt shredder with solid blades, so that you can process even most difficult matter. Check that the power of the motor matches the ability of your shredder. Actually, you'll only want a shredder if you intend to process hard material food waste for example bones. Or else, you save lots of money by selecting a machine without shredder.

An effective machine should in addition have a mixing chamber, power heaters, a gas exhaler and a liquid fertilizer squeezer. The various components of the machine that come into connection with organic matter have to be made from stainless. This can prevent them from rust and may extend the useful lifetime of your machine.

Since composting in not just a mechanical process, you must ask all manufacturers of these equipment for their compost quality certificate. Here is the only method to make sure you're gonna produce high-quality compost.

As a result machines aren't cheap, you shouldn't buy yours from the first supplier you encounter. Always seek for around three quotes from different manufacturers. Moreover, browse the work experience and also the client references of companies on your shortlist. Even though such machines should feature a good warranty, it's usually better to make the buy from an established manufacturer with an effective customer support department.

Choosing the right compost making machine depends upon several factors like the raw materials you're going to use, the kind of area you live in, along with your willingness to make the compost manually. In case you desire to make compost to market it to third parties, you'll need a different kind of equipment compared to the average homeowner looking to compost their waste.

To begin with, you have to determine the amount of matter you want to process every day. Compost machines for commercial and industrial purposes can process from 25 kg per day to 2 tonnes each day. Because this is a significant wide variety, you must narrow it down by determining your actual needs. Always allow some room for growth, if your business develop faster than expected. It wouldn't be too nice to outgrow your equipment in the 1st year of activity. Here are details of compost machines for commercial and industrial purposes https://compostturnermachine.com/commercial-compost-machine/

The productivity rates are another thing to remember when you shop around to find the best machine to make compost. If you want each of the speed you will get, you'd better make an effort to purchase a fully automatic machine. In the event that productivity doesn't matter just as much, you might like to pick a semi-automatic machine instead.

Whatever your decision, ensure that you pick a machine featuring a powerful inbuilt shredder with solid blades, so that you can process even most difficult matter. Check that the power of the motor matches the ability of your shredder. Actually, you'll only want a shredder if you intend to process hard material food waste for example bones. Or else, you save lots of money by selecting a machine without shredder.

An effective machine should in addition have a mixing chamber, power heaters, a gas exhaler and a liquid fertilizer squeezer. The various components of the machine that come into connection with organic matter have to be made from stainless. This can prevent them from rust and may extend the useful lifetime of your machine.

Since composting in not just a mechanical process, you must ask all manufacturers of these equipment for their compost quality certificate. Here is the only method to make sure you're gonna produce high-quality compost.

As a result machines aren't cheap, you shouldn't buy yours from the first supplier you encounter. Always seek for around three quotes from different manufacturers. Moreover, browse the work experience and also the client references of companies on your shortlist. Even though such machines should feature a good warranty, it's usually better to make the buy from an established manufacturer with an effective customer support department.

Cow Dung Processing Machine Working Principle

Essential Guide on Costs of Whole Sets of Cow Dung Processing Machines

Provided you can implement cow dung processing machines successfully into the business operations, it is possible to are in position to see fantastic profits. However, many professionals in the market are unaware of the technicalities behind dung processing machinery. If you’re seeking to make the most from these useful machines, you have to take proactive steps to teach yourself in regards to the costs associated with these appliances. With this in mind, here is an important guide about the costs of whole sets of cow dung processing machines.

Dependant upon the dung processing machines, you’ll see high variations in operating costs. Certain machines require a lot of power, ultimately causing very high operating costs. Sometimes, the outputs of this equipment is sufficient so that you can justify these expensive fees. However, other times, a machine is merely inefficient and unjustifiably produces high operational costs. You have to develop the capability to examine different models of those machines to evaluate whether or not their associated costs are justifiable, and so, profitable for your company.

There are numerous manufacturers of cow dung processing machines, however, not all of these manufacturers are trustworthy. You should take proactive steps to remove low-quality manufacturers that are infamous in the sector for creating machines that don’t meet standard. These machines could cost high numbers of capital, hence you don’t desire to waste any money on substandard machines. Doing a bit of industry research, you shouldn’t have much difficulty ascertaining which brands are notorious for producing unreliable cow dung machines.

One large cost associated with whole sets of cow dung processing machines is maintenance costs. All machines require maintenance every now and again. Maintenance ensures that the processing machine is not merely working at peak capacity, but additionally makes certain that it won’t malfunction in the near future. Malfunctioning machines can spell financial disaster for just about any business that relies heavily on revenue from dung processing. Make sure that you take into account the varying degrees of maintenance fees related to most of the popular processing machines available on the market currently.

The profitability margins on whole groups of cow dung processing machines are quite high in comparison with other revenue generators in the industry. However, you should always be conservative with regards to financing selections for these appliances. You definitely don’t desire to predicate financing on consistently realizing high margins with these machines. Always look at the worst-case scenario in terms of anything with regards to credit. Hence, always secure the smallest rates possible when financing any acquisition of dung processing machines to deliver both you and your team peace of mind.

The market for cow dung processing machines looks immensely strong in recent times. Now is an excellent a chance to finance some acquisitions of such machines to bolster in the revenue generation potential of the company. However, always make sure that you’re informed concerning the decisions you are making through the entire investment process. Make sure to remember the key points outlined to assure you’ll receive the best processing machines out there.

Provided you can implement cow dung processing machines successfully into the business operations, it is possible to are in position to see fantastic profits. However, many professionals in the market are unaware of the technicalities behind dung processing machinery. If you’re seeking to make the most from these useful machines, you have to take proactive steps to teach yourself in regards to the costs associated with these appliances. With this in mind, here is an important guide about the costs of whole sets of cow dung processing machines.

Dependant upon the dung processing machines, you’ll see high variations in operating costs. Certain machines require a lot of power, ultimately causing very high operating costs. Sometimes, the outputs of this equipment is sufficient so that you can justify these expensive fees. However, other times, a machine is merely inefficient and unjustifiably produces high operational costs. You have to develop the capability to examine different models of those machines to evaluate whether or not their associated costs are justifiable, and so, profitable for your company.

There are numerous manufacturers of cow dung processing machines, however, not all of these manufacturers are trustworthy. You should take proactive steps to remove low-quality manufacturers that are infamous in the sector for creating machines that don’t meet standard. These machines could cost high numbers of capital, hence you don’t desire to waste any money on substandard machines. Doing a bit of industry research, you shouldn’t have much difficulty ascertaining which brands are notorious for producing unreliable cow dung machines.

One large cost associated with whole sets of cow dung processing machines is maintenance costs. All machines require maintenance every now and again. Maintenance ensures that the processing machine is not merely working at peak capacity, but additionally makes certain that it won’t malfunction in the near future. Malfunctioning machines can spell financial disaster for just about any business that relies heavily on revenue from dung processing. Make sure that you take into account the varying degrees of maintenance fees related to most of the popular processing machines available on the market currently.

The profitability margins on whole groups of cow dung processing machines are quite high in comparison with other revenue generators in the industry. However, you should always be conservative with regards to financing selections for these appliances. You definitely don’t desire to predicate financing on consistently realizing high margins with these machines. Always look at the worst-case scenario in terms of anything with regards to credit. Hence, always secure the smallest rates possible when financing any acquisition of dung processing machines to deliver both you and your team peace of mind.

The market for cow dung processing machines looks immensely strong in recent times. Now is an excellent a chance to finance some acquisitions of such machines to bolster in the revenue generation potential of the company. However, always make sure that you’re informed concerning the decisions you are making through the entire investment process. Make sure to remember the key points outlined to assure you’ll receive the best processing machines out there.

Subscribe to:

Posts (Atom)