Organic inorganic compound fertilizer is a kind of compound fertilizer produced by the process flow of organic fertilizer and NPK fertilizer, which is mainly composed of organic matter and inorganic fertilizer. Blood acid is the main organic matter in organic-inorganic compound fertilizer with body acid. Nitrogen, phosphorus, potassium and other substances are added in the mechanical processing. This kind of compound fertilizer has higher nutrient utilization rate and has effect on soil fertilization.

Blood acid is a macromolecular compound formed by the decomposition of dead animals and plants by microorganisms and chemical reactions. It widely exists in peat soil, peat and lignite. Blood acid contains a variety of active groups, which has the characteristics of acidity, hydrophilicity, cation exchange and physiological activity. Blood acid can stimulate the root growth of crops, make the root system develop, absorb nutrients, and make the plant grow and resist stress. Blood acid contains carbon, nitrogen, sulfur and other important elements needed by crops, which can be used to process and produce corresponding organic fertilizer. Lactic acid, nitrogen, phosphorus and potassium compound fertilizers containing multiple nutrients can be produced by adding nitrogen, phosphorus and potassium to processing materials containing body acid, such as peat soil. Blood acid organic-inorganic compound fertilizer can absorb nutrients which can not be directly absorbed by crops. After biotransformation, nutrients are rapidly provided and absorbed by crops.

Raw material treatment of organic fertilizer

The raw materials (such as peat, peat soil, brown sugar pond mud, etc.) are mixed with livestock manure, added with 15% ammonia water and fermentation bacteria, mixed and put into the fermentation tank, which is turned over by the composting machine during the fermentation process. After fermentation, lactic acid organic raw materials were obtained.

Technology of organic and inorganic compound fertilizer with hexutanoic acid

Comminution and mixing: fermentation compost and inorganic fertilizer are crushed. A mixture of organic, inorganic and other nutrients.

Granulation: the mixed compound fertilizer powder is sent into the organic fertilizer complex to make the fertilizer into particles.

Drying and cooling: the particles formed by the granulator enter the dryer. Blood acid organic fertilizer granules were dried to 10-20% moisture content. The dried particles are then sent to the cooler and cooled to normal temperature.

Screening: screening machine screen out inappropriate particles, qualified particles into the coating process.

Coating: the coating machine uses organic vegetable oil as coating material to coat acid compound fertilizer particles.

Packaging: finished products and organic-inorganic compound fertilizer can be directly packaged and stored.

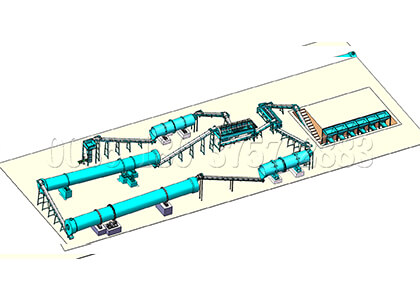

Acid organic inorganic compound fertilizer production line

Technical characteristics of organic and inorganic compound fertilizer with hetuvic acid

The organic compound fertilizer produced by this process can produce some enzymes and organic acids in the soil, which makes the soil well ventilated and has strong permeability. The production line of organic-inorganic compound fertilizer has strong continuity, convenient operation and low production cost.